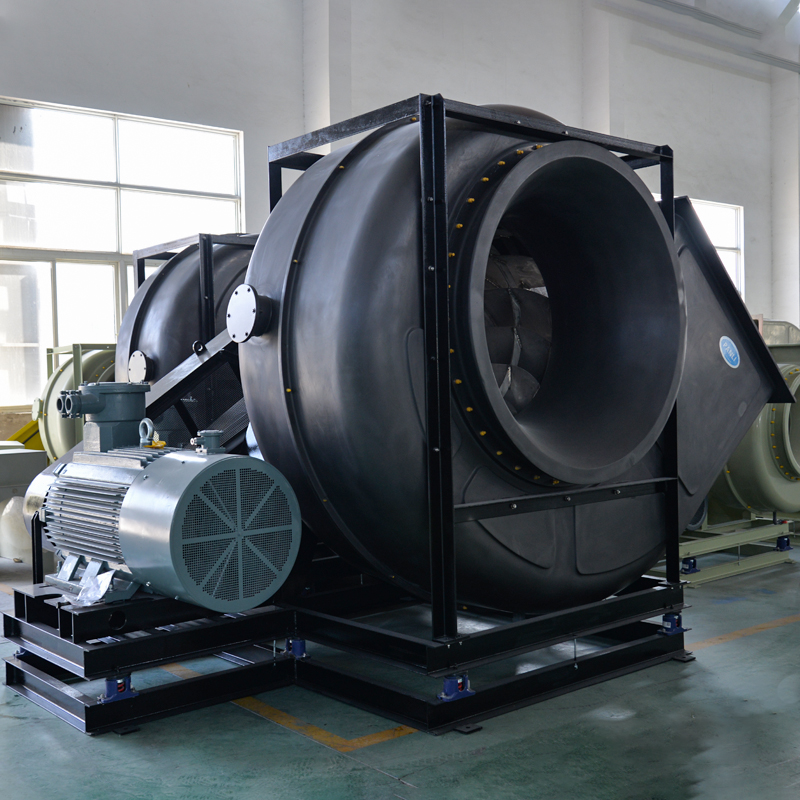

مروحة طرد مركزي مصنوعة من الألياف الزجاجية مقاومة للانفجار

مروحة طرد مركزي مصنوعة من الألياف الزجاجية مقاومة للانفجار

- طراز المروحة: FB1400C

- حجم هواء المروحة: 72704~101763CMH

- ضغط المروحة: 2813~2223 باسكال

- مستوى التوازن: ≤ 2.5 مم/ثانية

- كفاءة المروحة: ≥ 84%

- درجة حرارة التشغيل: ≤ 80 درجة مئوية

- سرعة المروحة: 1000 دورة في الدقيقة

- قوة المحرك: 110 كيلو واط

- قطر مجرى الهواء: DN1400*1500

مقدمة المنتج

01 مراقبة المواد الخام

المواد الخام: وفقا لتكوين الوسيط، حدد المواد الخام راتينج الألياف الزجاجية النقية من الدرجة فينيلستر، والاستخدام الداخلي لمواد ألياف الكربون مقاومة للانفجار، والحد من خطر مقاومة الانفجار، والحد من الرفض، مع محرك تنظيم سرعة تحويل التردد المقاوم للانفجار، وسهولة التركيب، والإنتاج على نطاق واسع من المنتجات، وعملية جديدة خفيفة الوزن وعالية القوة.

02 مواصفات المنتج

وفقًا للمعيار الوطني "GB3836.2-2010"، يمكن التشغيل المستمر لمدة 24 ساعة دون انقطاع، مع قرص مانع للتسرب FRP مدمج، لتجنب ظاهرة تسرب الغاز الخاصة، والتشغيل السلس، ودعم تخصيص المنتج، ويمكن تلبية مواصفات العملاء، والمتانة.

03 الخدمة وما بعد البيع

خدمة استشارية على مدار 24 ساعة عبر الإنترنت، توفر اختيار تكنولوجيا المروحة، ودعم حجم قياس المروحة البديلة من الباب إلى الباب، وحل مشاكل العملاء، والاستجابة خلال ساعتين، والصيانة من الباب إلى الباب في غضون 72 ساعة، وإجراء حالة تشغيل المعدات والتفتيش بانتظام، وضمان مدى الحياة، والتسليم اللوجستي الوطني، وخالية من القلق بعد البيع.

مروحة الطرد المركزي المقاومة للانفجار والمصنوعة من الألياف الزجاجية هي جهاز تهوية مقاوم للتآكل، مُصمم للبيئات الخطرة والقابلة للاشتعال، حيث قد توجد غازات أو أبخرة متفجرة. تجمع هذه المروحة بين سلامة المكونات الكهربائية والميكانيكية المقاومة للانفجار، ومقاومة البلاستيك المقوى بالألياف الزجاجية (FRP) الكيميائية، مما يجعلها مثالية للمصانع الكيميائية، وتصنيع البطاريات، وورش الطلاء، وأنظمة عادم المختبرات.

تعمل المروحة وفقًا لمبدأ الطرد المركزي: يدخل الهواء إلى الدافع محوريًا ويُطرد شعاعيًا بفعل قوة الطرد المركزي، محولًا الطاقة الحركية إلى ضغط ثابت. صُنع الدافع والغلاف من بلاستيك مقوى بالألياف الزجاجية، مما يوفر قوة شد عالية، وهيكلًا خفيف الوزن، ومقاومة فائقة للغازات المسببة للتآكل مثل حمض الهيدروكلوريك (HCl)، وكبريتات الكبريت (SO₂)، والأمونيا (NH₃). المحرك الكهربائي المقاوم للانفجار، والمصنف وفقًا لمعايير مثل Ex d IIB T4 أو Ex d IIC T4، مُحكم الغلق تمامًا ومُثبت خارج مسار تدفق الهواء المسبب للتآكل لمنع مصادر الاشتعال من ملامسة الغازات القابلة للاشتعال.

لتعزيز السلامة، تُصنع جميع المكونات المعدنية - مثل العمود، وأدوات التثبيت، وأغطية المحامل - من سبائك الألومنيوم أو الفولاذ المقاوم للصدأ المقاومين للشرر. ويتمتع الدافع بتوازن ديناميكي لمنع الشرر والاهتزاز الناتجين عن الاحتكاك. ويُوضع غطاء المحمل خارج مجرى الهواء، مع أنظمة تبريد اختيارية بالهواء أو الماء، لضمان التشغيل الآمن والمستمر. وتُحمى الوصلات الكهربائية بصناديق توصيل مقاومة للانفجار وأنابيب محكمة الغلق للحفاظ على سلامة النظام.

تشمل معايير الأداء عادةً معدلات تدفق هواء تتراوح بين 1000 و80000 متر مكعب/ساعة، وضغوط تتراوح بين 600 و4000 باسكال، حسب تصميم الطراز. تُستخدم مراوح الطرد المركزي المقاومة للانفجار والمصنوعة من الألياف الزجاجية على نطاق واسع في أنظمة التهوية الخطرة، وأنظمة عادم بخار المذيبات، ومرافق تخزين المواد الكيميائية، مما يوفر مقاومة كيميائية وحماية من الانفجار. يضمن دمجها بين مقاومة التآكل والسلامة من الانفجار التي توفرها الألياف الزجاجية المقواة بألياف زجاجية أداءً موثوقًا به طويل الأمد في ظل الظروف الصناعية الخطرة.