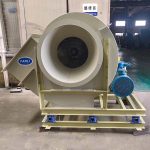

Boiler Centrifugal Fan

Boiler Centrifugal Fan

- Fan model: TPC8.0C

- Fan air volume: 21886~35415CMH

- Fan pressure: 2873~2133Pa

- Balance level: ≤ G2.5 mm/s

- Fan efficiency: ≥ 84%

- Operating temperature: ≤ 80%

- Fan speed: 1870rpm

- Motor power: 30KW

- Air duct diameter: DN800~DN900 M

- Applicable location: metal processing plant

Product Introduction

The shell is made of Q235 carbon steel material, which has strong high-temperature and corrosion resistance characteristics. It is equipped with a metal impeller and sealed packing, ensuring stable operation and avoiding leakage of special gases. It can be customized according to customer requirements and optimized for free. It can be used in high-temperature environments such as metal processing plants.

Panli Fan has a production base of 30000 square meters, with 10 years of experience in producing fans. It is a manufacturing enterprise that integrates sales, research and development, production, and service. It has a complete scientific research and quality management system, a high-quality R&D team, and has been awarded titles such as "Suzhou Brand Enterprise" and "Top 100 Soviet Enterprises in Jiangsu Province".

24-hour customer service online, one-on-one manufacturer service, free selection of fans, nationwide logistics delivery and installation. If there are any malfunctions or other issues, you can contact after-sales personnel for on-site repair within 72 hours to solve various problems encountered by customers, with a lifetime warranty and worry free after-sales service.

A Boiler Centrifugal Fan is a key component in industrial and commercial boiler systems, responsible for supplying combustion air or exhausting flue gases. It operates on the centrifugal principle, where the impeller draws in air axially and discharges it radially at increased pressure. The fan ensures optimal combustion efficiency, stable flame characteristics, and controlled airflow balance within the boiler furnace. It is designed to operate continuously under high temperature, dust, and vibration conditions.

The structure of a boiler centrifugal fan typically includes an impeller, casing, inlet bell, shaft, bearing assembly, and drive motor. The impeller is fabricated from carbon steel, stainless steel, or heat-resistant alloy, depending on the operating temperature—often up to 350°C or higher. The volute casing is reinforced with ribs to withstand high static pressure, while the bearing housing is positioned outside the hot airflow and equipped with air- or water-cooling devices to maintain lubrication stability.

To achieve optimal performance, boiler fans are carefully matched to the boiler’s air supply and exhaust characteristics. Two main types are commonly used: induced draft fans (ID fans) for flue gas extraction and forced draft fans (FD fans) for combustion air supply. Both require precise control of air volume and pressure. The drive motor can be connected via coupling or belt system, and speed control is often achieved using variable-frequency drives (VFDs) to improve energy efficiency.

Performance capacities typically range from 2,000 m³/h to 200,000 m³/h, with pressures from 1,000 to 12,000 Pa, depending on boiler size and type. Boiler centrifugal fans are widely applied in power plants, biomass boilers, chemical reactors, drying kilns, and incineration systems. Designed for high efficiency, heat resistance, and stable continuous operation, these fans ensure safe and efficient combustion performance across diverse thermal process applications.