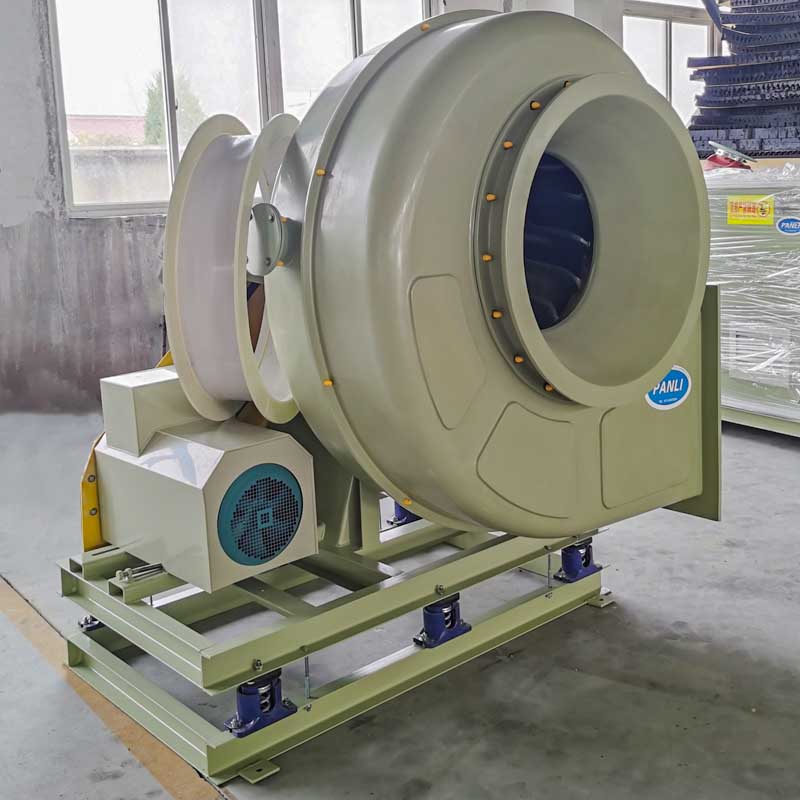

Ventilator otporan na kiseline i alkalije od fiberglasa

Ventilator otporan na kiseline i alkalije od fiberglasa

- Fan model: FB710C

- Zapremina zraka ventilatora: 15511~25364 cm/h

- Fan pressure: 2619~1504 Pa

- Nivo ravnoteže: ≤ 2,5 mm/s

- Efikasnost ventilatora: ≥84%

- Operating temperature: ≤80%

- Brzina ventilatora: 1910 obrtaja u minuti

- Snaga motora: 22KW

- Air duct diameter: DN700~DN850 M

Predstavljanje proizvoda

01 Product Features

Fiberglass acid and alkali resistant fan with petal type packing shaft seal, good sealing performance, special gas leakage prevention, can be used in factories, laboratories and other special occasions, shell and impeller made of fiberglass material, integrated mold molding, manual reinforcement process, corrosion and acid prevention, strict control of equipment operating efficiency.

02 Honors and Qualifications

Panli ten years focus on fan production and research and development, won the "Su Shang top 100 enterprises", with substantial patents "a centrifugal fan exhaust gas collection device", China energy-saving product certification, China energy efficiency label certification, EU CE certification and other certificates +30 patents certification, quality assurance.

03 Postprodajne usluge

U slučaju kvara opreme, pravovremeni kontakt, korisnička podrška 24 sata dnevno online, 72 sata na licu mjesta za održavanje, Panli ventilator redovno vrši istragu i inspekciju stanja rada opreme, profesionalna tehnologija za rješavanje svih vrsta problema s kojima se susreću kupci, nacionalna logistička dostava, osiguranje kvaliteta.

A Fiberglass Acid and Alkali Resistant Fan is an industrial-grade centrifugal ventilation unit specifically engineered to handle acidic and alkaline gases generated during chemical processing, metal plating, and wastewater treatment. Constructed entirely from fiberglass-reinforced plastic (FRP), this fan provides outstanding corrosion resistance, lightweight structure, and high mechanical strength, ensuring long-term stability under aggressive chemical conditions.

The impeller, volute casing, and inlet cone are molded from vinyl ester or epoxy-modified FRP, which offers excellent protection against strong acids such as HCl, H₂SO₄, and HNO₃, as well as alkaline vapors like NaOH or NH₃. The impeller typically adopts a backward-curved or radial blade design for high efficiency and smooth operation. The volute casing is formed as a seamless, reinforced FRP shell that prevents gas leakage and resists mechanical deformation under pressure.

Key metallic components such as the shaft, bolts, and bearing housings are made of stainless steel or anti-corrosive coated steel, ensuring mechanical reliability. The bearing seat is mounted outside the airflow, completely isolated from corrosive gases, and equipped with high-temperature grease or sealed bearings for long service intervals. The motor can be coupled directly or via a belt drive, with optional explosion-proof or anti-static configurations available for hazardous areas.

The fan’s performance range typically covers airflows from 800 to 60,000 m³/h and static pressures from 400 to 4,000 Pa. Its design provides low vibration, stable performance, and energy-efficient operation. Common applications include chemical scrubbers, acid mist removal, fume extraction in plating workshops, and laboratory ventilation. With its superior chemical resistance and structural integrity, the Fiberglass Acid and Alkali Resistant Fan delivers reliable, maintenance-free operation in the harshest industrial atmospheres.