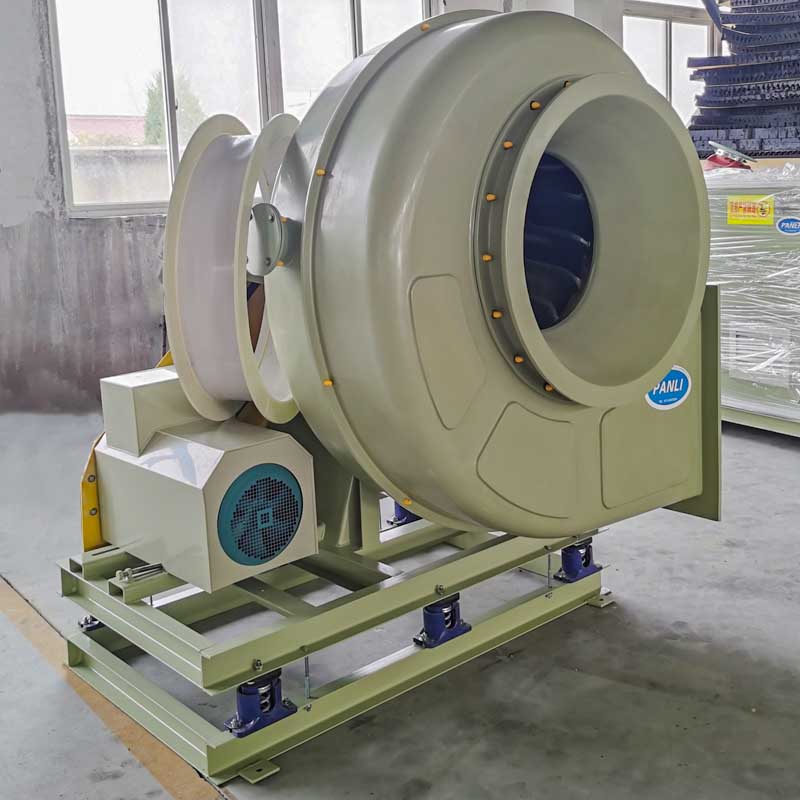

Ventilador resistent a àcids i àlcalis de fibra de vidre

Ventilador resistent a àcids i àlcalis de fibra de vidre

- Model de ventilador: FB710C

- Volum d'aire del ventilador: 15511 ~ 25364 CMH

- Pressió del ventilador: 2619~1504 Pa

- Nivell d'equilibri: ≤ 2,5 mm/s

- Eficiència del ventilador: ≥84%

- Temperatura de funcionament: ≤80%

- Velocitat del ventilador: 1910 rpm

- Potència del motor: 22 kW

- Diàmetre del conducte d'aire: DN700 ~ DN850 M

Introducció del producte

01 Característiques del producte

Ventilador de fibra de vidre resistent a l'àcid i als àlcalis amb segellat d'eix d'embalatge tipus pètal, bon rendiment de segellat, prevenció especial de fuites de gas, es pot utilitzar en fàbriques, laboratoris i altres ocasions especials, carcassa i impulsor fets de material de fibra de vidre, modelat de motlle integrat, procés de reforç manual, prevenció de la corrosió i l'àcid, control estricte de l'eficiència operativa dels equips.

02 Honors i qualificacions

Panli s'ha centrat durant deu anys en la producció de ventiladors i la investigació i el desenvolupament, ha guanyat el premi "Su Shang top 100 enterprises", amb patents importants com "un dispositiu de recollida de gasos d'escapament de ventilador centrífug", certificació de productes d'estalvi d'energia de la Xina, certificació d'etiquetes d'eficiència energètica de la Xina, certificació CE de la UE i altres certificats +30 patents de certificació, garantia de qualitat.

03 Servei postvenda

Si l'equip falla en funcionament, contacteu puntualment, servei d'atenció al client les 24 hores del dia, servei de manteniment del lloc les 72 hores, el ventilador de Panli realitza regularment investigacions i inspeccions de l'estat del funcionament de l'equip, tecnologia professional per resoldre tot tipus de problemes que troben els clients, lliurament logístic nacional, garantia de qualitat.

Un ventilador de fibra de vidre resistent a àcids i àlcalis és una unitat de ventilació centrífuga de grau industrial dissenyada específicament per gestionar gasos àcids i alcalins generats durant el processament químic, el recobriment de metalls i el tractament d'aigües residuals. Construït completament amb plàstic reforçat amb fibra de vidre (FRP), aquest ventilador ofereix una resistència a la corrosió excepcional, una estructura lleugera i una alta resistència mecànica, garantint una estabilitat a llarg termini en condicions químiques agressives.

L'impel·lent, la carcassa de la espiral i el con d'entrada estan modelats amb FRP modificat amb èster de vinil o epoxi, que ofereix una excel·lent protecció contra àcids forts com HCl, H₂SO₄ i HNO₃, així com vapors alcalins com NaOH o NH₃. L'impel·lent normalment adopta un disseny de fulla radial o corbada cap enrere per a una alta eficiència i un funcionament suau. La carcassa de la espiral està formada com una closca de FRP reforçada i sense costures que evita les fuites de gas i resisteix la deformació mecànica sota pressió.

Els components metàl·lics clau, com ara l'eix, els cargols i les carcasses dels coixinets, estan fets d'acer inoxidable o d'acer amb recobriment anticorrosiu, cosa que garanteix la fiabilitat mecànica. El seient del coixinet està muntat fora del flux d'aire, completament aïllat dels gasos corrosius i equipat amb greix d'alta temperatura o coixinets segellats per a intervals de servei llargs. El motor es pot acoblar directament o mitjançant una transmissió per corretja, amb configuracions opcionals a prova d'explosió o antiestàtiques disponibles per a zones perilloses.

El rang de rendiment del ventilador normalment cobreix cabals d'aire de 800 a 60.000 m³/h i pressions estàtiques de 400 a 4.000 Pa. El seu disseny proporciona vibracions baixes, un rendiment estable i un funcionament energèticament eficient. Les aplicacions habituals inclouen fregadors químics, eliminació de boira àcida, extracció de fums en tallers de galvanoplàstia i ventilació de laboratoris. Amb la seva resistència química superior i integritat estructural, el ventilador de fibra de vidre resistent a àcids i àlcalis ofereix un funcionament fiable i sense manteniment en les atmosferes industrials més dures.