Εργαστηριακός ανεμιστήρας

Εργαστηριακός ανεμιστήρας

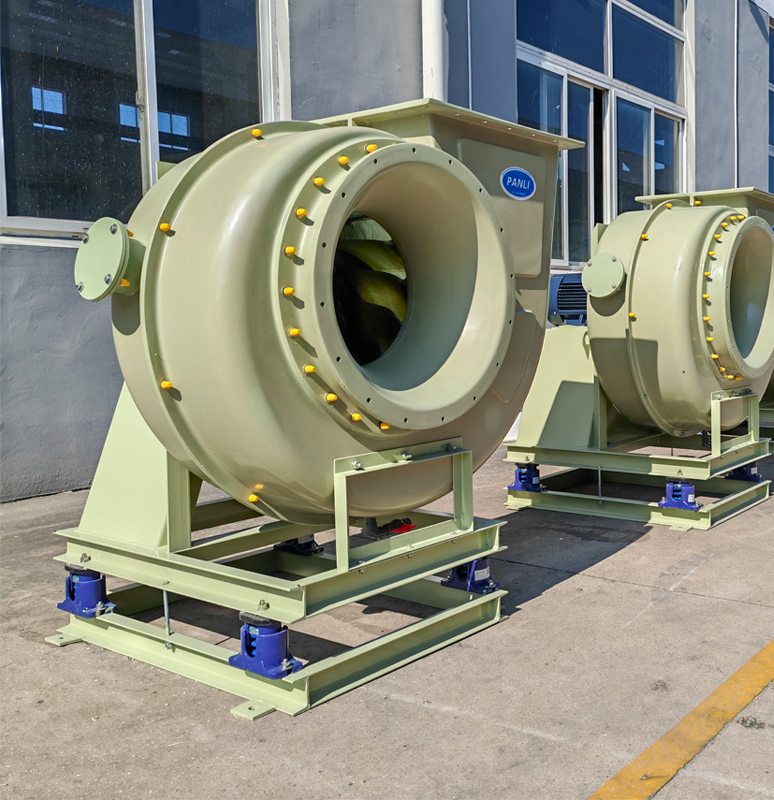

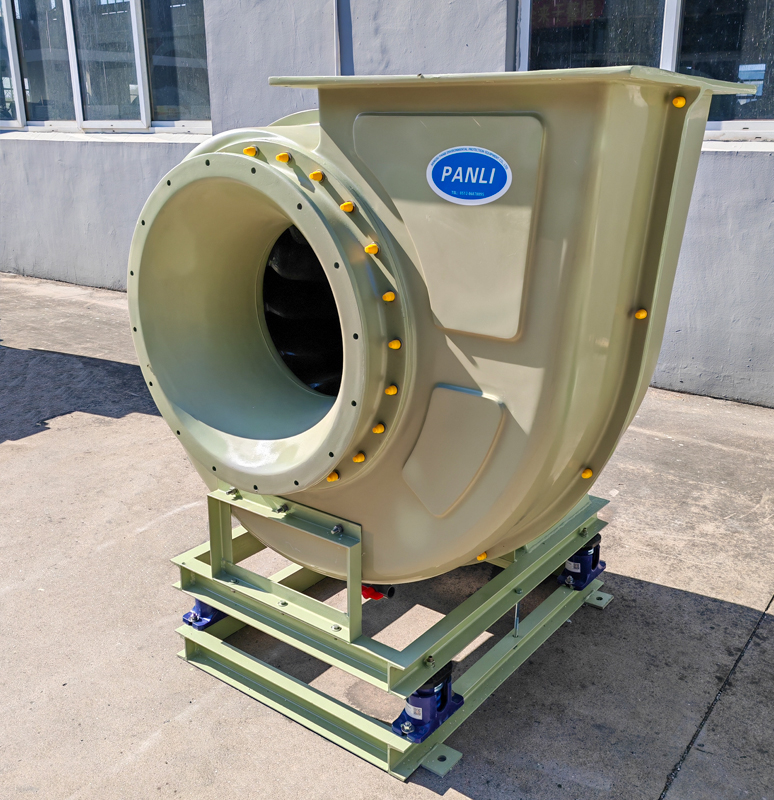

- Μοντέλο ανεμιστήρα: FB710A

- Χωρητικότητα αέρα ανεμιστήρα: 11775~19255 CMH

- Πίεση ανεμιστήρα: 1509~867 Pa

- Ισορροπία ρότορα: ≤ 2,5 mm/s

- Θερμοκρασία λειτουργίας: ≤ 60℃

- Πρότυπο θορύβου: ≤ 75dB

- Ταχύτητα ανεμιστήρα: 1460 σ.α.λ.

- Ισχύς κινητήρα: 11KW

- Διάμετρος αεραγωγού: DN600~DN700

- Αξεσουάρ ανεμιστήρα: αδιάβροχο καπάκι ή ελαστική μαλακή άρθρωση, κ.λπ. [προσαρμοσμένο]

Εισαγωγή προϊόντος

Ειδικός ανεμιστήρας ενισχυμένου με υαλοβάμβακα (FRP) για εργαστήρια. Είναι κατασκευασμένος εξ ολοκλήρου από FRP, η ακρίβεια πάχους των λεπίδων είναι ±0,3 mm. Το υλικό κόβεται με μηχανή χάραξης πέντε αξόνων. Ο ποιοτικός έλεγχος είναι αυστηρός. Συμμορφώνεται με το πρότυπο ενεργειακής απόδοσης της ετικέτας. Προσαρμόζεται όπως απαιτείται για τη βελτιστοποίηση του κόστους και την εξοικονόμηση κατανάλωσης ηλεκτρικής ενέργειας. Υποβάλλεται σε αυστηρές εργοστασιακές δοκιμές και παραδίδεται αφού πληροί τις απαιτήσεις.

Η πιστοποίηση CNEX για αντιεκρηκτικά και άλλες αναγνωρισμένες πιστοποιήσεις δοκιμών, είναι μια "επιχείρηση υψηλής τεχνολογίας".

24 ώρες την ημέρα online οικεία εξυπηρέτηση, 1 ώρα για ανάλυση και εξάλειψη προβλημάτων, 48~ ατομική παράδοση σε εθνικό επίπεδο μέσω logistics, να είστε σίγουροι για τη χρήση, να μην ανησυχείτε μετά τη χρήση, να χρησιμοποιείτε ξανά, να εξοικονομείτε κόστος.

Εφαρμόσιμα σενάρια

Ο εργαστηριακός ανεμιστήρας χρησιμοποιείται στο εργαστηριακό περιβάλλον δοκιμών για την απορρόφηση, την επεξεργασία και την εκκένωση πειραματικών χημικών συστατικών. Αυτό το είδος προϊόντος σχεδιάζεται και κατασκευάζεται για εργαστηριακή έρευνα και ανάπτυξη, χαμηλό θόρυβο, χαμηλή δόνηση, χαμηλό κόστος, σταθερή λειτουργία, 24ωρη απρόσκοπτη λειτουργία, μείωση της πιθανότητας ζημιάς, συχνή συντήρηση, εξοικονόμηση λειτουργικών εξόδων.

Ένας εργαστηριακός ανεμιστήρας είναι μια συσκευή ακριβείας για τη διαχείριση του αέρα, σχεδιασμένη για τη διατήρηση ασφαλούς και καθαρού αερισμού σε εργαστηριακά περιβάλλοντα. Σκοπός του είναι η εξαγωγή μολυσμένου αέρα από τους απαγωγούς, τους αγωγούς εξαγωγής και τους πειραματικούς θαλάμους, εξασφαλίζοντας ελεγχόμενη αρνητική πίεση και ασφαλείς συνθήκες χειρισμού. Οι εργαστηριακοί ανεμιστήρες μπορούν να κατασκευαστούν από υαλοβάμβακα, πολυπροπυλένιο (PP), PVC ή ανοξείδωτο χάλυβα, ανάλογα με τον τύπο των χημικών ατμών και τις απαιτήσεις αντοχής στη διάβρωση του εργαστηρίου.

Ο πιο συνηθισμένος σχεδιασμός είναι ο φυγοκεντρικός, χρησιμοποιώντας μια πτερωτή με οπίσθια καμπύλη ή ακτινική πτερωτή για σταθερή πίεση και αποτελεσματική παροχή αέρα. Οι κινητήρες επιλέγονται για χαμηλό θόρυβο και συνεχή λειτουργία, συχνά με έλεγχο συχνότητας για ρυθμιζόμενη ροή αέρα. Το περίβλημα του ρουλεμάν είναι απομονωμένο από τη ροή αέρα και ολόκληρος ο ανεμιστήρας έχει σχεδιαστεί για εύκολο καθάρισμα και συντήρηση. Για εργαστήρια που χειρίζονται πτητικές χημικές ουσίες, ο ανεμιστήρας μπορεί να εξοπλιστεί με κινητήρες αντιεκρηκτικούς και πτερωτές χωρίς σπινθήρες.

Ο έλεγχος θορύβου και η απομόνωση κραδασμών αποτελούν αναπόσπαστα στοιχεία σχεδιασμού. Οι ανεμιστήρες συνήθως εγκαθίστανται με εύκαμπτους συνδέσμους και σιγαστήρες για την ελαχιστοποίηση της μετάδοσης κραδασμών στη δομή του κτιρίου. Τα υλικά περιβλήματος όπως το FRP ή το PVC εξασφαλίζουν χημική αντοχή, ενώ οι παραλλαγές από ανοξείδωτο χάλυβα χρησιμοποιούνται για περιβάλλοντα καθαρών χώρων και βιολογικής έρευνας που απαιτούν αποστειρούμενες επιφάνειες.

Η απόδοση κυμαίνεται από 300 m³/h έως 30.000 m³/h, με πιέσεις μεταξύ 200 και 2.000 Pa. Οι εργαστηριακοί ανεμιστήρες είναι απαραίτητοι σε χημικά εργαστήρια, ερευνητικά ιδρύματα, εγκαταστάσεις ιατρικών δοκιμών και κέντρα δοκιμών παραγωγής. Διατηρώντας αξιόπιστη απόδοση καυσαερίων, συγκράτηση χημικών καυσαερίων και σταθερή ροή αέρα, οι εργαστηριακοί ανεμιστήρες διασφαλίζουν την ασφάλεια των χειριστών και τον έλεγχο της ποιότητας του αέρα - κρίσιμοι παράγοντες στις σύγχρονες επιστημονικές και βιομηχανικές ερευνητικές εγκαταστάσεις.