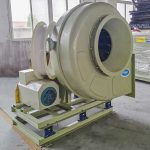

Ventilador centrífugo de fibra de vidrio FRP

Ventilador centrífugo de fibra de vidrio FRP

- Fan model: FB1250C

- Fan air volume: 49162~68811 CMH

- Fan pressure: 2544~1851 Pa

- Fan direction: left rotation 45 degrees -L

- Nivel de equilibrio: ≤ 2,5 mm/s

- Eficiencia del ventilador: ≥ 84%

- Temperatura de funcionamiento: ≤ 80 ℃

- Fan speed: 950rpm

- Potencia del motor: 55 kW

- Air duct diameter: DN1200 [Recommended ±10%]

Introducción del producto

01 Tecnología de materiales

Fiberglass centrifugal ventilator is made of vinylester grade vinylester resin, pure fiberglass material, shell mold molding, impeller five-axis engraving technology, speeding test, anti-burst test, rotor balance ≤2.0mm/s, long service cycle, stable wind speed, high wind pressure, good ventilation effect.

02 Desarrollo de la empresa

Base de producción de 30.000 metros cuadrados, producción anual de 10.000 unidades, estricto control de calidad de los ventiladores, gestión de trazabilidad humanizada, la empresa cuenta con la certificación y pruebas AMCA para ventiladores, entrega rápida en 2 días para pedidos urgentes de la marca, servicios de consultoría en línea las 24 horas, ingenieros personalizados en 72 horas para garantizar la calidad y resolver diversos problemas de los usuarios, protección posventa.

The FRP Fiberglass Centrifugal Fan is an industrial-grade air handling device designed to transport corrosive gases and vapors with high efficiency and reliability. The fan’s construction uses fiberglass-reinforced plastic, ensuring resistance to acids, alkalis, and most chemical vapors found in industrial production. It operates on the centrifugal principle, where air is drawn in axially and discharged radially through a volute housing, producing high static pressure with controlled flow rates.

This centrifugal fan features an aerodynamically optimized impeller with backward-curved or radial blades, designed for energy-efficient operation and low noise. The impeller and casing are manufactured through precision molding, ensuring excellent dimensional stability and consistent performance even under fluctuating loads. Bearings are mounted outside the airflow path to minimize exposure to corrosive gases, extending operational lifespan and reducing maintenance frequency.

The motor options include standard IP55 motors, explosion-proof types, or variable frequency drives (VFDs) for adjustable speed control. Depending on system requirements, the fan can be mounted horizontally or vertically. Air capacities typically range from 500 m³/h to 100,000 m³/h, with pressures between 200–3,500 Pa. The smooth internal surface of the FRP housing ensures minimal air resistance and prevents chemical residue buildup.

Common applications include chemical processing plants, battery manufacturing, semiconductor production, pickling lines, and laboratory exhaust systems. Its high chemical resistance and long operational life make the FRP Centrifugal Fan an ideal solution for demanding environments that require stable airflow and minimal downtime.