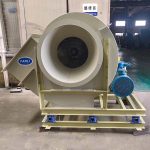

Ventilador metálico de alta presión

Ventilador metálico de alta presión

- Modelo de ventilador: TPE8.0C

- Volumen de aire del ventilador: 25000 CMH

- Presión del ventilador: 3500 Pa

- Nivel de equilibrio: ≤ G2,5 mm/s

- Eficiencia del ventilador: ≥ 84%

- Temperatura de funcionamiento: ≤ 80%

- Velocidad del ventilador: 1960 rpm

- Potencia del motor: 37 kW

- Diámetro del conducto de aire: DN800~DN900 M

- Lugar de aplicación: planta de procesamiento de metales

Introducción del producto

Panli high-pressure metal fans have a wide range of applications, suitable for various working conditions, efficient and energy-saving (energy-saving), creating profits and cost saving after-sales service for you.

Escenarios aplicables

Widely used for exhaust gas treatment and purification, sewage deodorization, etc.

The High Pressure Metal Fan is a robust centrifugal-type industrial blower engineered for high-pressure ventilation and air delivery in demanding industrial environments. Unlike conventional low-pressure fans, this model is optimized for strength, durability, and long-term stability. The entire structure—including the impeller, housing, and base frame—is fabricated from heavy-duty metal, typically carbon steel or stainless steel, which provides excellent mechanical integrity under continuous operation.

The fan’s impeller features multiple backward-curved blades precisely welded or riveted to the hub, forming a rigid assembly that minimizes aerodynamic loss. During operation, air enters the impeller axially and is expelled radially under centrifugal force, resulting in significant static pressure. The volute casing is carefully shaped to convert dynamic energy into pressure energy efficiently. The fan is powered by an industrial-grade motor mounted directly or via a coupling, depending on installation requirements.

One of the key advantages of metal construction is its thermal stability and resistance to deformation, even under high static pressure or elevated temperature. The metallic casing can endure vibration, shock, and continuous duty, making it ideal for factories, furnaces, and heavy industrial systems. The surfaces are treated with anti-corrosion coatings such as epoxy or zinc-rich primer to extend service life in humid or chemically active environments. Where noise reduction is required, acoustic enclosures or silencers can be added.

High pressure metal fans are frequently used in combustion air supply, dust collection systems, industrial kilns, textile drying, and pneumatic conveying. Typical performance specifications include pressure outputs up to 12,000 Pa and flow capacities between 500 and 80,000 m³/h. They maintain high efficiency across varying loads due to their well-balanced impeller design and aerodynamic optimization. The metallic structure ensures stability, minimal maintenance, and reliability in continuous operation scenarios, where synthetic or plastic fans cannot meet the performance demands.