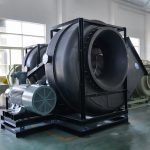

Ventilador centrífugo industrial

Ventilador centrífugo industrial

- Modelo de ventilador: TPB 4.5C

- Volumen de aire del ventilador: 5644~8891 CMH

- Presión del ventilador: 1512-1152 Pa

- Nivel de equilibrio: ≤ G2,5 mm/s

- Eficiencia del ventilador: ≥ 84%

- Temperatura de funcionamiento: ≤ 80%

- Velocidad del ventilador: 2200 rpm

- Potencia del motor: 4KW

- Diámetro del conducto de aire: DN400~DN550 M

- Ubicación aplicable: Ventilación de alta temperatura en plantas químicas.

Introducción del producto

Adoptando un revestimiento resistente a la temperatura y a la corrosión, equipado con embalaje sellado, evita fugas de gas, funciona sin problemas, ahorra costos de mano de obra y es adecuado para ventilación de alta temperatura y transporte de gas en plantas químicas, que contienen gases ácidos y tiene un estricto control de calidad.

Con 10 años de experiencia en la fabricación de turbinas eólicas y la colaboración con empresas de la lista Fortune 500, la empresa cuenta con una base de producción física de aproximadamente 20 000 m². Ha obtenido certificaciones como la Certificación de Productos de Conservación de Energía de China, la Certificación de Etiquetado de Eficiencia Energética de China, la Certificación CE de la UE y más de 30 patentes, lo que garantiza su calidad.

Venta directa del fabricante, servicio de atención al cliente en línea las 24 horas, cotización en 1 hora, brindando soluciones de selección y diseño, garantía prometida de un año, mantenimiento posventa en el sitio, entrega logística a nivel nacional, tutorial de guía de instalación en el sitio.

Un ventilador centrífugo industrial es un dispositivo esencial para el movimiento de aire, utilizado en plantas de fabricación, centrales eléctricas e industrias de proceso para ventilación, transporte de aire, eliminación de polvo y apoyo a la combustión. Su principio de funcionamiento se basa en la aceleración centrífuga: el aire entra axialmente en el impulsor por la entrada y es impulsado radialmente hacia afuera por las aspas giratorias, aumentando su velocidad y presión antes de ser descargado por la salida. El ventilador convierte la energía mecánica del motor en energía de presión del flujo de aire, garantizando un funcionamiento eficiente y continuo en condiciones exigentes.

Los componentes principales incluyen el impulsor, la carcasa, el cono de entrada, el eje, los cojinetes y el sistema de accionamiento. El diseño del impulsor (hacia adelante, hacia atrás o radial) determina la eficiencia y las características de presión. Los ventiladores centrífugos industriales generalmente se fabrican en acero al carbono, acero inoxidable o acero aleado, según las necesidades ambientales, como la humedad, la temperatura o los gases corrosivos. El impulsor y la carcasa están equilibrados dinámicamente para reducir la vibración y el ruido, mejorando así la fiabilidad operativa.

Para adaptarse a diversas aplicaciones industriales, estos ventiladores pueden configurarse con transmisión directa, transmisión por correa o transmisión por acoplamiento. Los rodamientos se montan en carcasas externas, a menudo equipadas con aletas de refrigeración o sistemas de lubricación para un funcionamiento continuo. Según la composición del aire, se aplican recubrimientos protectores o galvanizados para resistir la corrosión y el desgaste. La selección del motor se adapta a las necesidades de la aplicación: se pueden instalar motores asíncronos estándar, variadores de frecuencia o motores a prueba de explosiones.

Los ventiladores centrífugos industriales se utilizan ampliamente en el procesamiento químico, la producción de cemento, la generación de energía, la fundición de metales, los sistemas de climatización (HVAC) y el secado de granos. Su capacidad de caudal de aire suele oscilar entre 1000 m³/h y más de 300 000 m³/h, con presiones de salida de entre 500 y 15 000 Pa. Diseñados para un funcionamiento continuo y de alta eficiencia, estos ventiladores ofrecen un rendimiento estable en diversas cargas y condiciones ambientales. Su robusta construcción y su precisa aerodinámica los convierten en componentes indispensables en los sistemas de ventilación y procesos industriales modernos.