Ventilador centrífugo de bajo ruido

Ventilador centrífugo de bajo ruido

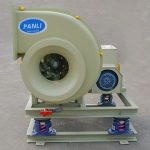

- Modelo de ventilador: THPB 4.5C

- Volumen de aire del ventilador: 1616~2680 CMH

- Presión del ventilador: 4672~4020 Pa

- Nivel de equilibrio: ≤ 2,5 mm/s

- Eficiencia del ventilador: ≥ 84%

- Velocidad del ventilador: 2900 rpm

- Potencia del motor: 5,5 kW

- Diámetro del conducto de aire: DN200~DN300 M

- Temperatura de funcionamiento: temperatura ambiente [se requieren instrucciones especiales para altas temperaturas]

Introducción del producto

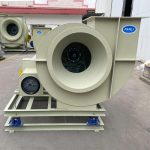

El diseño de los ventiladores centrífugos de bajo ruido cumple con los requisitos de la norma JB/T 8690-1998 sobre límites de ruido para ventiladores de ventilación industrial. Los materiales utilizados son acero de grado Q235A/B, y la entrada de aire está equipada con un silenciador que reduce el ruido entre 5 y 15 decibelios. Para cumplir con los requisitos ambientales, se ha diseñado una solución personalizada que facilita la carga y descarga de los ventiladores centrífugos.

Panli Fan cuenta con diez años de experiencia en fabricación y ha sido reconocida como una de las "100 Mejores Empresas de la Provincia de Jiangsu". Ha obtenido más de 30 certificaciones de patentes, incluyendo patentes sustanciales como "Dispositivo Silenciador Importado para Ventiladores Centrífugos" y "Dispositivo de Recolección de Gases de Escape para Ventiladores Centrífugos". Optimiza el diseño y facilita la personalización de especificaciones.

Ofrecemos servicios de diseño gratuitos y logística nacional para la instalación in situ. El departamento de posventa investigará e inspeccionará el estado de funcionamiento del ventilador. Si surge algún problema, como un fallo de funcionamiento, puede contactar con el servicio de atención al cliente, que le ofrece servicio en línea las 24 horas. En un plazo de 72 horas, podrá acudir a su domicilio para resolver el problema, y tecnología profesional resolverá los problemas que puedan surgir, garantizando un uso sin preocupaciones.

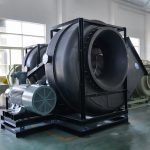

Un ventilador centrífugo de bajo ruido está diseñado para ofrecer alta eficiencia y flujo de aire, a la vez que minimiza las emisiones acústicas, lo que lo hace ideal para entornos donde se requiere rendimiento y un funcionamiento silencioso. Funciona con el mismo principio centrífugo que los ventiladores estándar (el aire entra axialmente en el impulsor y se acelera hacia afuera a través de la voluta), pero incorpora tecnologías avanzadas de reducción de ruido aerodinámico y estructural.

El impulsor está diseñado con álabes curvados hacia atrás o aerodinámicos, lo que reduce significativamente la turbulencia y el ruido de frecuencia de paso de los álabes. La carcasa de la voluta presenta una curvatura suave que minimiza la separación del flujo de aire. Se utilizan materiales como acero galvanizado o acero inoxidable para garantizar la integridad estructural, y las superficies internas pueden incluir revestimientos insonorizantes o capas amortiguadoras de vibraciones. Todo el conjunto del ventilador se equilibra con precisión para eliminar la resonancia mecánica.

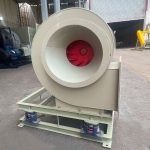

Los ventiladores centrífugos de bajo ruido suelen emplear aisladores de vibraciones de goma o resorte, conexiones de conductos flexibles y silenciadores en las secciones de entrada y salida. Los cojinetes se lubrican con grasa de baja fricción y el motor puede montarse en un bastidor independiente con aislamiento acústico. El rendimiento del aire se optimiza mediante análisis de dinámica de fluidos computacional (CFD), lo que garantiza una mínima pérdida aerodinámica. Los motores energéticamente eficientes, que suelen cumplir con las normas IE3 o IE4, mejoran aún más el funcionamiento silencioso y reducen la generación de calor.

Estos ventiladores se utilizan ampliamente en sistemas de climatización (HVAC), laboratorios, salas blancas, hospitales, plantas de procesamiento de alimentos y talleres de fabricación de productos electrónicos. Los caudales de aire típicos oscilan entre 500 m³/h y 100 000 m³/h, con presiones de 300 Pa a 3000 Pa, según el tamaño y la velocidad del modelo. Combinando alta eficiencia, bajas vibraciones y un nivel mínimo de ruido, los ventiladores centrífugos silenciosos garantizan un entorno de trabajo cómodo y silencioso sin sacrificar el rendimiento ni la fiabilidad.