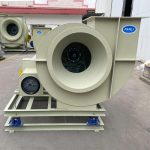

Ventilateur centrifuge anticorrosion

Ventilateur centrifuge anticorrosion

- Fan model: TPC 10 C

- Fan air volume: 39047~54653 CMH

- Fan pressure: 3277~2355 Pa

- Niveau d'équilibre : ≤ G2,5 mm/s

- Température de fonctionnement : ≤ 80 ℃

- Fan efficiency: ≥ 84.6%

- Vitesse du ventilateur : 1450 tr/min

- Motor power: 45KW

- Air duct diameter: DN900~DN1100 M

- Fan color: light blue [supports specified color]

Présentation du produit

Panli carbon steel ventilation fans have obtained various patent certifications and technical certifications for their high efficiency, high performance, low noise, and low vibration. Carbon steel ventilation fans are widely used in the after-sales service of places with corrosive gases containing acid, alkali and chemical components, such as pharmaceuticals, precision electronics, metal processing, PCB circuit boards, sewage deodorization, semiconductor processes, electroplating and pickling.

Scénarios applicables

Largement utilisé dans les industries pharmaceutiques et chimiques, l'électronique de précision, le traitement des métaux, les cartes de circuits imprimés, la désodorisation des eaux usées, les procédés de semi-conducteurs, la galvanoplastie et le décapage, et d'autres lieux avec des gaz corrosifs contenant des composants acides, alcalins et chimiques pour le service après-vente.

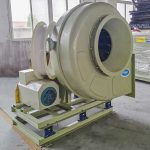

The Anti-Corrosion Centrifugal Fan is specifically engineered for environments exposed to aggressive gases, vapors, or chemical particulates. Its housing and impeller are constructed from premium anti-corrosive materials such as fiberglass reinforced plastic (FRP), polypropylene (PP), or 316 stainless steel, ensuring outstanding resistance to acid, alkali, and saline atmospheres. The fan’s robust design maintains high performance even under continuous operation in chemical plants, laboratories, and wastewater treatment facilities.

This fan features a backward-curved impeller that delivers stable airflow with high efficiency and low noise. Each component is designed for smooth air passage, minimizing turbulence and energy loss. The anti-corrosion coating or material composition prevents degradation over time, extending service life and maintaining consistent air volume output.

With a modular design, the Anti-Corrosion Centrifugal Fan allows for easy installation, inspection, and maintenance. Its customizable options — including motor type, air volume, and outlet direction — make it adaptable for various ventilation systems. It is the ideal solution where reliability, chemical resistance, and energy efficiency are crucial for long-term operation.