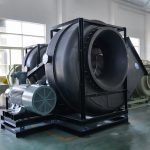

Ventilateur centrifuge en fibre de verre

Ventilateur centrifuge en fibre de verre

- Modèle de ventilateur : FB1000C

- Débit d'air du ventilateur : 29 975 à 43 274 m³/h

- Pression du ventilateur : 3213~1912 Pa

- Efficacité du ventilateur : ≥ 84%

- Niveau d'équilibrage : ≤ 2,5 mm/s

- Température de fonctionnement : ≤ 80 ℃

- Vitesse du ventilateur : 1320 tr/min

- Puissance du moteur : 37 kW

- Diamètre du conduit : DN1000±10%

- Matériau du ventilateur : acier au verre pur (FRP)

Présentation du produit

01 Technologie des matériaux

Le ventilateur centrifuge en fibre de verre est fabriqué à partir de résine vinylester de qualité vinylester, de fibre de verre pure, par moulage de coque, avec une technologie de gravure à cinq axes de la turbine, un test de vitesse, un test anti-éclatement, un équilibrage du rotor ≤ 2,0 mm/s, un long cycle de service, une vitesse de vent stable, une pression de vent élevée et un bon effet de ventilation.

02 Développement de l'entreprise

Base de production de 30 000 mètres carrés, production annuelle de 10 000 unités, contrôle strict de la qualité des ventilateurs, gestion de la traçabilité simplifiée, l'entreprise a passé les tests et la certification AMCA pour ses ventilateurs, livraison rapide des commandes urgentes de la marque sous 2 jours, services de consultation en ligne 24 heures sur 24, ingénierie dédiée sur mesure sous 72 heures pour une assurance qualité, afin de résoudre les différents problèmes des utilisateurs, protection après-vente.

Un ventilateur centrifuge en fibre de verre est un appareil de traitement d'air haute performance et résistant à la corrosion, conçu pour l'extraction industrielle, la ventilation de process et les systèmes de purification d'air. Fabriqué en plastique renforcé de fibres de verre (PRFV), il offre une combinaison unique de durabilité chimique, de résistance mécanique et d'efficacité aérodynamique, ce qui le rend idéal pour les usines chimiques, les laboratoires, les installations maritimes et les systèmes de contrôle environnemental.

Ce ventilateur fonctionne selon le principe centrifuge : l’air pénètre axialement dans la roue et est expulsé radialement par la force centrifuge. La roue en PRV, moulée d’une seule pièce, est dotée de pales incurvées vers l’arrière pour une pression et un rendement élevés. Le carter est réalisé en PRV moulé sans soudure, garantissant une étanchéité parfaite et une excellente résistance à la dégradation chimique. Le moteur peut être entraîné directement ou par courroie, selon les exigences d’installation.

Tous les composants métalliques, y compris l'arbre et la visserie, sont en acier inoxydable, tandis que les roulements sont placés hors du flux d'air dans des carters étanches. Cette conception garantit un fonctionnement fluide et silencieux, sans vibrations. Parmi les accessoires disponibles en option figurent des silencieux, des raccords flexibles, des amortisseurs et des moteurs antidéflagrants pour les environnements à risque d'explosion de gaz.

Ses performances varient de 1 000 à 120 000 m³/h de débit d'air et de 400 à 5 000 Pa de pression statique. Le ventilateur centrifuge en fibre de verre est largement utilisé pour l'extraction des brouillards acides, la ventilation des procédés chimiques, les systèmes d'épuration et les applications de traitement d'air pur. Il offre une résistance durable à la corrosion, un rendement énergétique élevé et une installation facile, ce qui en fait une solution fiable pour les systèmes de ventilation industrielle modernes.