High Temperature Centrifugal Fan

High Temperature Centrifugal Fan

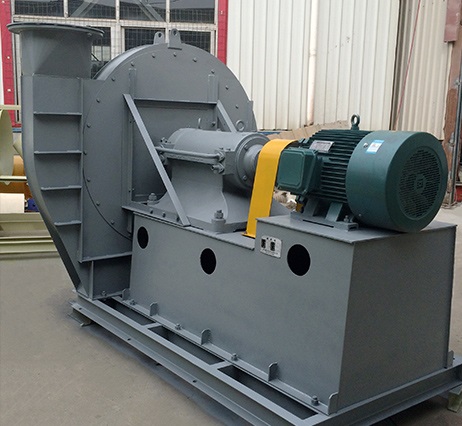

- Fan model: THPA 8.0 D

- Fan air volume: 2924~6330 CMH

- Fan pressure: 11351~15276 Pa

- Balance level: ≤ G2.5 mm/s

- Operating temperature: ≤ 250 ℃ (circulating water cooling)

- Fan efficiency: ≥ 82.4%

- Fan speed: 2900rpm

- Motor power: 55KW

- Air duct diameter: DN200~DN300 M

- Material used: Q235A/B-carbon steel [supports customized insulation]

High-temperature process airstreams are conveyed using specially designed high-temperature centrifugal fans that can handle temperatures of up to 1800 degrees F. Many industrial processes rely on high-temperature process heat. High-temperature operations such as heat treating, stress relieving, industrial furnaces, and ovens use convection to circulate heated air within the chamber.

Fans and blowers not properly designed for this purpose will catastrophically fail when used at temperatures above their design.

The High Temperature Centrifugal Fan is purpose-built for conveying air or gas at elevated temperatures—typically in the range of 100°C to 450°C, and in special designs up to 600°C. This fan utilizes a centrifugal impeller mechanism that delivers stable pressure and flow even under thermal stress. To ensure durability and safety, the fan incorporates heat-resistant materials, thermally isolated bearings, and advanced cooling systems.

The impeller and casing are generally constructed from heat-treated carbon steel, stainless steel, or alloy steel, depending on the temperature class. The bearing chamber is separated from the airflow path by an extended shaft and air cooling or water-cooling structure to prevent lubricant degradation. Special high-temperature grease and precision bearings ensure long service life. The motor is mounted outside the hot airflow, connected via a coupling or belt drive to isolate heat transfer.

Thermal expansion and vibration are key design challenges in high-temperature fans. To address this, the structure includes expansion joints, flexible connections, and stress-relief ribs. The impeller undergoes high-temperature balancing tests to prevent deformation at speed. All weld seams are performed using heat-resistant welding materials and undergo nondestructive inspection. Surface coatings are formulated for oxidation resistance and heat reflection.

High temperature centrifugal fans are widely applied in industrial ovens, furnaces, glass manufacturing, metallurgical kilns, drying systems, and thermal treatment plants. They deliver airflow volumes from 1,000 m³/h to 120,000 m³/h and static pressures from 1,000 to 8,000 Pa. These fans ensure reliable air circulation, combustion support, or exhaust extraction in thermally intensive processes. Their robust design guarantees stable operation, extended service life, and minimal maintenance under severe temperature conditions.