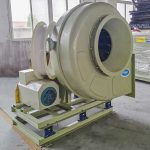

Antikorozijas stiklšķiedras ventilators

Antikorozijas stiklšķiedras ventilators

- Fan model: GFB630C

- Transmisijas režīms: siksnas piedziņa

- Ventilatora gaisa tilpums: 10996~20477 CMH

- Fan pressure: 2823~1433 Pa

- Darba temperatūra: ≤80 ℃

- Fan efficiency: ≥82.3%

- Vibrācijas vērtība: ≦2,5 mm/s

- Ventilatora ātrums: 1870 apgr./min

- Motora jauda: 15 kW

- Air duct diameter: DN600 [Recommended with PVC shock absorber soft connection]

Produkta ievads

01CQC Energy-saving product certification

Anticorrosive fiberglass fan test in line with GB19761-2009 national standard, fan manufacturer equipment, CQC China energy-saving product certification, continuous operation of 24 hours troublefree operation, maintenance and long service cycle, energy saving, the whole unit testing computer stress and strain analysis, stable fan operation.

02 Material accessories selection

OIL bath closed bearing seat, lubricating protection bearing, and shaft core is not corroded by corrosive gas, wear resistance, strict quality control, reduce the frequency of failure, modular production, unified specifications, complete parts and materials, support 2 days fast delivery, reduce operating costs, ensure installation and use.

03 Provide service team

Support on-site measurement of fan performance, vibration, noise and other tests, including test reports, and a number of delivery data is complete, prevent failure before it happens, ensure that the fan operates in the best condition, tailored for users to ensure that the fan operates at the best efficiency point, avoid surge damage area.

The Anticorrosive Fiberglass Fan is designed to deliver reliable ventilation performance in environments where chemical corrosion, humidity, or salt exposure can damage standard metal fans. Built entirely from fiberglass-reinforced plastic (FRP), it features superior durability and chemical resistance, making it the ideal solution for chemical factories, wastewater treatment plants, pickling lines, and marine ventilation systems.

The centrifugal-type fan uses a molded fiberglass impeller with backward-curved blades for high efficiency and energy savings. The volute casing and inlet bell are formed as a seamless FRP shell, providing excellent structural integrity and air-tightness. The surface is coated with a UV- and chemical-resistant gel coat for extended service life. For enhanced corrosion protection, the fan’s rotating shaft and bolts are made from stainless steel, while bearings are mounted externally in sealed housings.

The motor can be standard or explosion-proof, depending on the operating environment. A belt drive or coupling transmission allows the motor to be isolated from the corrosive gas stream. Optional accessories include sound absorbers, dampers, and flexible connectors to minimize vibration transmission. The fan’s aerodynamic design ensures stable performance under continuous operation, even in acidic or alkaline atmospheres.

Typical airflow ranges from 800 to 60,000 m³/h, with pressures from 300 to 3,000 Pa. The anticorrosive fiberglass fan offers the perfect balance of chemical durability, mechanical strength, and low maintenance cost. Its ability to operate reliably in corrosive air conditions makes it indispensable in chemical processing, semiconductor manufacturing, and environmental ventilation systems.