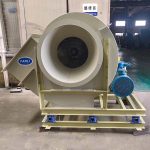

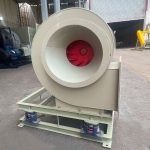

Høytrykks antikorrosjonsvifte i glassfiber

Høytrykks antikorrosjonsvifte i glassfiber

- Viftemodell: YHFB 1120C

- Vifteluftvolum: 28343~33153 CMH

- Viftetrykk: 5520~4223 Pa

- Rotorbalanse: ≤ 2,5 mm / s

- Enhetsvibrasjon: ≤ 6,3 mm /s

- Driftstemperatur: ≤80 ℃

- Vifteeffektivitet: ≥78,3%

- Viftehastighet: 1480 o/min

- Motoreffekt: 75 kW

- Luftkanaldiameter: DN700~DN800 mm [motstand 7Kpa kan dimensjoneres]

Produktintroduksjon

01FRP Råvarer

Glassfiberforsterket plast høytrykks antikorrosjonsvifte råmaterialer laget av vinylesterharpiks, all glassfiberforsterket plastharpiks, i henhold til kombinasjonen av kjemiske molekylære elementer, brukt i faktiske forhold, syre- og alkalisk eksosutslippsbehandling, 60 000 timer med buksefri drift, bruk av trefase frekvensomformingshastighetskontrollmotor, femakset graveringsprosesslys og høy styrke.

02 Kvalifikasjonssertifisering

Høytrykksvifteakselens sideende trenger en lekkasjesikker enhet. Tetningsmetoder inkluderer: FRP-pakningstetning, mekanisk tetning, karbonring, nitrogen, grafitt, labyrint, returluft og andre tetningsenheter. Forskning og utvikling av "petal seal" gasslekkasjesikker enhet, med praktisk patentanerkjennelse, testrapportdetaljer.

03 Vedlikehold etter salg

Produsentservice, analyse og feilsøking innen 2 timer, 48~ inspeksjon, livslang garanti, logistikk fra dør til dør, rettidig service, bekymringsfri bruk.

Høytrykksviften i glassfiber med korrosjonsbeskyttelse er en presisjonskonstruert sentrifugalvifte som er konstruert for å levere høy statisk trykkluftstrøm i kjemiske eller korrosive miljøer. Viftehuset, løpehjulet og spiralhuset er konstruert av førsteklasses FRP-materialer, forsterket med kontinuerlige glassfibre for eksepsjonell mekanisk styrke og korrosjonsbestandighet. Dette muliggjør langvarig drift i sur gass, alkalisk damp eller løsemiddelholdige atmosfærer.

Viftens høytrykksimpeller bruker bakoverbøyde blader designet for optimalisert luftkompresjon, noe som sikrer stabil ytelse over et bredt spekter av driftsforhold. Den aerodynamiske designen minimerer turbulens og vibrasjoner, noe som resulterer i effektiv energiomforming og redusert støy. Huset og bladene er belagt innvendig med et glatt, kjemikaliebestandig gelbelegg, som ikke bare forbedrer korrosjonsmotstanden, men også minimerer friksjonstap i luftstrømmen.

Viften drives av en motor av industrikvalitet og støtter både direktedrift og remdrift. Eksplosjonssikre og variabelfrekvensalternativer er tilgjengelige for å imøtekomme flyktige eller energifølsomme prosesser. Lagrene er forseglet og beskyttet mot gasstrømmen, noe som sikrer lang levetid selv under kontinuerlig kjemisk eksponering. Enhetens driftsområde dekker strømningshastigheter opptil 90 000 m³/t og statiske trykk så høye som 4500 Pa.

Vanlige bruksområder inkluderer ventilasjon i galvaniseringslinjer, avtrekk av syretåke, gassutvinning fra kjemiske reaktorer og skrubbersystemer for avgass. Høytrykksviften i glassfiber med korrosjonsbeskyttelse er den foretrukne løsningen der tradisjonelle vifter i stål eller aluminium svikter på grunn av korrosjon, og tilbyr en ideell balanse mellom høytrykkskapasitet, strukturell stabilitet og kjemisk holdbarhet.