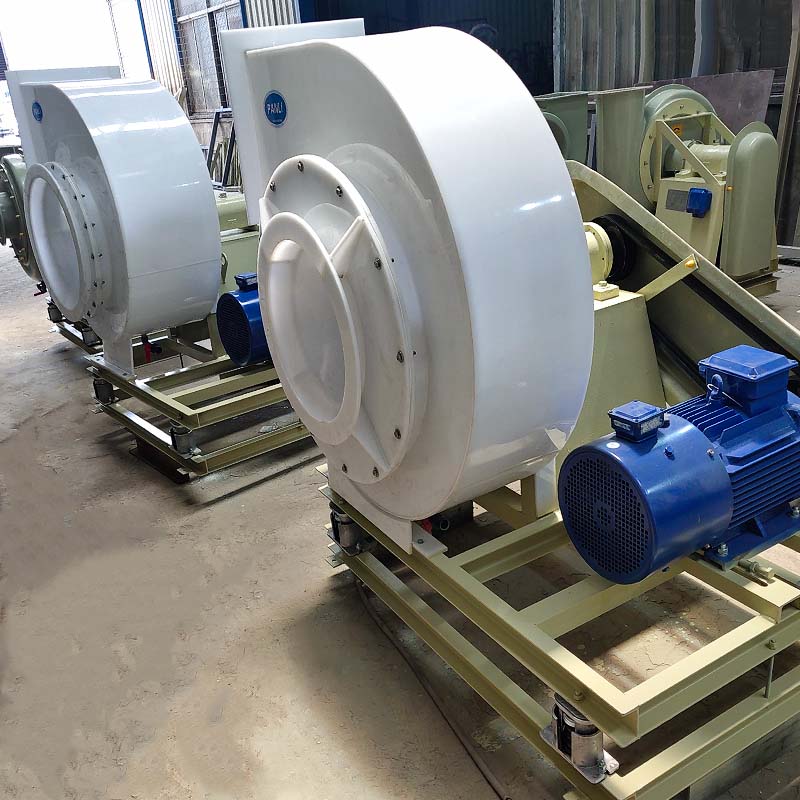

PP-plastvifte

PP-plastvifte

- Viftemodell: FP560C

- Vifteluftvolum: 6318~12455 CMH

- Viftetrykk: 1447~562 Pa

- Balansenivå: ≤ 2,5 mm/s

- Driftstemperatur: ≤ 60 ℃

- Viftehastighet: 1450 o/min

- Motoreffekt: 3 kW

- Vifteinntak: DN550

- Viftemateriale: ren polypropylen [melkehvit]

Produktintroduksjon

PP-plastvifter er tilpasset med fargede råmaterialer og plater, med flere alternativer for å matche ventilasjonssystemet, og opprettholder en enhetlig og vakker fargetone med det overordnede systemet. De brukes hovedsakelig i kjemiske fabrikker, som kjemiske laboratorier, biologiske laboratorier, farmasøytiske laboratorier, virusvaksinalaboratorier og andre miljøer. Uavhengige laboratoriesystemer er uunnværlig utstyr for avgassbehandling av ulike typer gasser, og forskning og utviklingsdesign kan ikke ignoreres.

PP-plastviften er en ventilasjonsenhet i industriell kvalitet, antikorrosjonsbestandig, designet for bruk i tøffe kjemiske eller fuktige miljøer. Denne viften er laget av polypropylen med høy tetthet og tilbyr utmerket motstand mot et bredt utvalg av korrosive gasser som saltsyre, svovelsyre og alkalidamper. Den installeres ofte i platinganlegg, gjødselfabrikker, kjemiske laboratorier og eksosbehandlingsanlegg.

Viftestrukturen er lett, men mekanisk robust. Huset, løpehjulet og innløpskonen er produsert ved hjelp av presisjonstermoforming og varmeplatesveising for å sikre lekkasjefri drift. Løpehjulet bruker bakoverbøyde blader for effektiv lufthåndtering, noe som minimerer turbulens og støy samtidig som det gir sterk trykkytelse.

Avhengig av installasjonskravene kan PP-plastviften konfigureres for aksiale eller sentrifugale luftstrømsmønstre. Motoren er beskyttet mot korrosive gasser via et forseglet hus eller en ekstern koblingsanordning. Denne designen forlenger motorens levetid og forbedrer driftssikkerheten. Viftens ytelse forblir konsistent selv under varierende temperatur- og fuktighetsforhold.

Fra et teknisk synspunkt oppnår PP-plastviften energieffektivitet og stabil ytelse gjennom aerodynamisk optimalisering og dynamisk balansering. Den kan integreres med frekvensomformere (VFD-er) for å regulere luftstrømmen i sanntid. Maksimal kontinuerlig driftstemperatur er omtrent 70 °C, med korte trykkstøt på opptil 80 °C.

Dens lave vedlikeholdskrav, kjemiske motstand og driftsstabilitet gjør PP-plastviften til en foretrukket løsning for kontinuerlige avtrekkssystemer i korrosive industri- og laboratoriemiljøer.