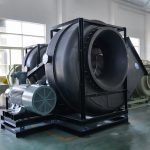

Ventilador de exaustão de fibra de vidro

Ventilador de exaustão de fibra de vidro

- Fan model: FB1450C

- Fan air volume: 67614~94640 CMH

- Fan pressure: 2433~1927 Pa

- Nível de equilíbrio: ≤ 2,5 mm/s

- Eficiência do ventilador: ≥ 84%

- Temperatura de operação: ≤ 80℃

- Fan speed: 930rpm

- Motor power: 90KW

- Air duct diameter: DN1400

- Fan color: Sand color[Support custom]

Apresentação do produto

01 Tecnologia de Materiais

Fiberglass tail gas fan adopts petal packing shaft seal, good sealing performance, gas leakage prevention, suitable for chemical plant, laboratory and other environment use, fiberglass shell and impeller, integrated mold forming, strength reinforcement process, anti-corrosion acid and alkali prevention, strict control of fan equipment operating efficiency.

02 Desenvolvimento da Empresa

Com patente substancial de "dispositivo de coleta de gases de exaustão de ventilador centrífugo", certificação de produto de economia de energia da China, certificação de selo de eficiência energética da China, garantia.

03 Serviço pós-venda

Caso o equipamento apresente falhas durante o funcionamento, entre em contato imediatamente. O serviço de atendimento ao cliente está disponível 24 horas por dia, online, e a manutenção no local pode ser realizada em até 72 horas. A Panli Fan realiza inspeções e verificações regulares do funcionamento dos equipamentos, contando com tecnologia especializada para solucionar todos os tipos de problemas enfrentados pelos clientes. Oferecemos entrega logística em todo o país e garantia de qualidade.

The Fiberglass Exhaust Fan is a high-performance ventilation system designed for continuous operation in environments where corrosive, humid, or contaminated air must be effectively extracted. Constructed from fiberglass-reinforced plastic (FRP), it delivers exceptional acid, alkali, and moisture resistance, making it an ideal choice for chemical plants, wastewater treatment stations, plating workshops, laboratories, and coastal facilities.

The fan structure includes a precision-molded impeller, volute casing, and inlet bell — all fabricated from corrosion-resistant fiberglass resin reinforced with continuous glass fibers. Depending on the gas type, vinyl ester or epoxy-modified resins are used to enhance resistance to acids such as HCl, H₂SO₄, and organic solvents. The smooth internal surface minimizes frictional losses, enhancing airflow efficiency and reducing operational noise.

The centrifugal impeller features backward-curved or radial blades, optimized through computational fluid dynamics (CFD) analysis to ensure high efficiency and stable pressure output. Bearings are mounted outside the corrosive airflow and housed in sealed chambers for protection and easy lubrication. The motor can be configured for direct-drive or belt-drive, and for hazardous atmospheres, explosion-proof or anti-static motors can be fitted.

Performance capacities typically range from 1,000 to 100,000 m³/h, with static pressures up to 4,000 Pa. This fan provides stable airflow, low vibration, and energy-efficient performance under continuous industrial duty. The Fiberglass Exhaust Fan is widely applied for acidic or alkaline gas extraction, general plant ventilation, odor removal systems, and scrubber exhaust, where its lightweight, corrosion-proof structure ensures long-term reliability with minimal maintenance.