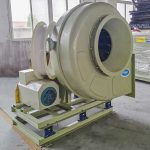

Caixa à prova de som para ventilador em fibra de vidro

Caixa à prova de som para ventilador em fibra de vidro

- Fan model: FB 900C

- Fan air volume: 37857~24053 CMH

- Fan pressure: 2658-1605 Pa

- Sentido de rotação do ventilador: Rotação para a esquerda de 180 graus – Direção A

- Nível de equilíbrio: ≤ 2,5 mm/s

- Temperatura de operação: ≤ 80 ℃

- Eficiência do ventilador: ≥ 82,2%

- Fan speed: 1620rpm

- Potência do motor: 30 kW

- Air duct diameter: DN800~DN1000 [supports customized appearance color]

Apresentação do produto

O ventilador de fibra de vidro da cabine à prova de som atende aos limites de ruído estabelecidos. O equipamento funciona continuamente por 24 horas, apresentando baixo ruído, baixa vibração, acabamento impecável e economia de energia. A cabine à prova de som foi testada de acordo com padrões computadorizados, e análises de ruído em medições reais foram realizadas para aprimorar o isolamento acústico do ventilador.

A inspeção de dutos tipo D é realizada utilizando um ventilador centrífugo, em conformidade com a norma GB-T1236-2000 para inspeção de dutos de ar. A carcaça e o rotor do ventilador centrífugo são fabricados em conjunto, com caixa de rolamentos banhada a óleo e sistema de refrigeração a ar. A produção industrial apresenta as mesmas especificações, operação conveniente, rapidez, baixo custo operacional e facilidade de substituição do ventilador centrífugo.

PANLI, who has advanced technology in wind turbines, and experienced senior experts, combine the two strengths; By combining precise calculations with the development of data acquisition software such as CAD, 3D, CFD, etc., tailored designs can be made to ensure the normal use of fans.

Cenários aplicáveis

Fiberglass reinforced plastic fan soundproof boxes are widely used and are commonly used in acidic and alkaline environments such as sewage deodorization, biological deodorization, pharmaceutical and chemical industries, electroplating and acid washing, university laboratories, electronic semiconductors, etc. Environmental pollution is becoming increasingly severe, and there are also considerable requirements for the noise generated by machinery. Soundproof box fans are currently widely used to reduce the degree of noise pollution, effectively block the spread of noise, move more stably, rotate more quietly, and are suitable for use in sewage deodorization and biological deodorization projects.

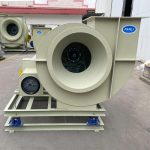

The Fiberglass Fan Soundproof Box is an advanced noise-reduction housing system designed for FRP or PP fans operating in chemical or corrosive environments. It integrates high-strength fiberglass-reinforced plastic (FRP) materials with multilayer acoustic insulation to provide both corrosion protection and superior sound suppression.

This soundproof enclosure is designed specifically for use with fans handling acidic, alkaline, or odor-laden exhaust gases, such as those found in plating workshops, laboratories, or environmental deodorization systems. The fiberglass casing resists chemical corrosion, UV degradation, and moisture penetration, ensuring long service life even in harsh conditions.

Internally, the soundproof box is lined with acoustic foam and perforated composite panels that absorb airborne and mechanical noise generated by fan operation. The design achieves significant sound attenuation—typically reducing noise by 15–25 dB(A)—without compromising ventilation performance.

The enclosure’s internal structure allows smooth airflow, preventing backpressure or turbulence. The fan motor can be mounted externally, with a sealed coupling to isolate electrical components from corrosive gases. Access panels are equipped with gasketed doors for easy maintenance while maintaining airtight integrity.

Engineered for performance, the Fiberglass Fan Soundproof Box combines chemical resistance, structural rigidity, and sound attenuation into one system. It is suitable for integration with FRP centrifugal fans, PP exhaust fans, or high-pressure FRP blowers, providing a quiet and corrosion-proof ventilation solution in industrial air purification systems.