Ventilador de aço carbono resistente a altas temperaturas

Ventilador de aço carbono resistente a altas temperaturas

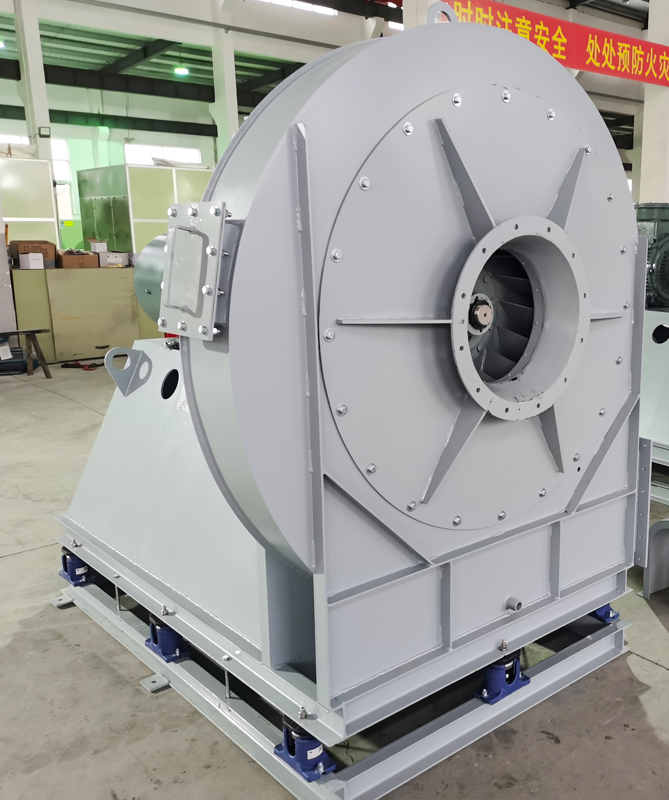

- Modelo do ventilador: THPB8.0D

- Volume de ar do ventilador: 21886~35415 cm³/h

- Pressão do ventilador: 2873~2133Pa

- Nível de equilíbrio: ≤ G2,5 mm/s

- Eficiência do ventilador: ≥ 84%

- Temperatura de operação: ≤ 80%

- Velocidade da ventoinha: 1870 rpm

- Potência do motor: 30 kW

- Diâmetro do duto de ar: DN800~DN900 m

- Local de aplicação: fábrica de processamento de metais

Apresentação do produto

Ventiladores de aço carbono resistentes a altas temperaturas são um produto especial para diversos setores industriais, e desenvolvemos modelos específicos para reduzir custos e aumentar seus lucros. Com uma abordagem focada no cliente, garantimos a satisfação total com nossos ventiladores. Com alto desempenho, especificações de projeto padronizadas, manutenção simplificada e um serviço pós-venda atencioso, somos a sua melhor opção no setor de ventiladores.

Cenários aplicáveis

Amplamente utilizado em coleta de poeira, exaustão de incineradores, exaustão de compostos orgânicos voláteis (VOCs), exaustão de alta temperatura, processos de semicondutores e fornecimento de ar forçado.

O ventilador de aço carbono resistente a altas temperaturas é um dispositivo de ventilação industrial robusto, projetado para suportar ambientes térmicos extremos, mantendo um desempenho aerodinâmico estável. Construído principalmente em aço carbono de alta qualidade, este ventilador combina resistência excepcional, tolerância ao calor e confiabilidade mecânica. Ele foi projetado para operação de longo prazo em aplicações onde as temperaturas do ar ou do gás excedem os limites padrão dos ventiladores — geralmente entre 150 °C e 500 °C.

O impulsor de aço carbono, reforçado com pás espessas e juntas soldadas, proporciona alta rigidez estrutural e mínima deflexão em alta velocidade. A carcaça do ventilador é fabricada a partir de chapas de aço cortadas com precisão, montadas por soldagem de penetração total e reforçadas com nervuras para suportar a expansão térmica e a vibração. O eixo e o sistema de rolamentos estão posicionados fora do fluxo de ar principal e incluem alojamentos de rolamentos refrigerados a ar e a água para garantir estabilidade de lubrificação contínua.

A construção em aço carbono deste ventilador oferece um equilíbrio entre custo-benefício e resistência térmica, superando as alternativas de alumínio ou plástico. O design incorpora camadas de isolamento térmico entre o motor e o corpo do ventilador, reduzindo a transferência de calor. Cada unidade é balanceada dinamicamente e testada sob condições de simulação de alta temperatura para verificar a estabilidade mecânica. O acabamento da superfície inclui um revestimento resistente a altas temperaturas para proteção contra oxidação, corrosão e incrustações.

Ventiladores de aço carbono resistentes a altas temperaturas são amplamente utilizados em fornos de tratamento térmico, fábricas de sinterização, linhas de processamento de vidro e sistemas de secagem. São adequados para o transporte de ar limpo, gases quentes ou ar levemente empoeirado sob condições severas de temperatura e pressão. As capacidades de vazão de ar variam tipicamente de 800 a 100.000 m³/h, com pressões estáticas entre 1.000 e 10.000 Pa. Seu design robusto, a seleção de materiais e a precisão de engenharia os tornam indispensáveis em indústrias que exigem alta resistência térmica e desempenho consistente do fluxo de ar.