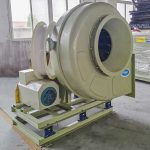

Ventilator din fibră de sticlă rezistent la coroziune, acid și alcali

Ventilator din fibră de sticlă rezistent la coroziune, acid și alcali

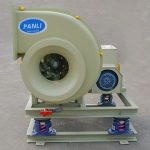

- Model ventilator: GFB1300C

- Volumul de aer al ventilatorului: 47000~70000 cm³/h

- Presiunea ventilatorului: 1800~2400Pa

- Eficiența ventilatorului: ≥ 84%

- Nivel de echilibru: ≤ 2,5 mm/s

- Temperatura de funcționare: ≤ 80℃

- Viteza ventilatorului: 980 rpm

- Putere motor: 55 kW

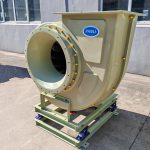

- Diametrul conductei: DN1200

- Material ventilator: oțel pur din sticlă (FRP)

Introducerea produsului

Ventilatorul din fibră de sticlă este utilizat pe scară largă în procesele de fibre de sticlă, extracția pământurilor rare, industria chimică și farmaceutică, dezodorizarea apelor uzate, fabricarea hârtiei în anaerobă, reciclarea acidului și alte medii gazoase corozive acido-bazice.

Scenarii aplicabile

Ventilatorul din fibră de sticlă este utilizat pe scară largă în procesele de fibre de sticlă, extracția pământurilor rare, industria chimică și farmaceutică, dezodorizarea apelor uzate, fabricarea hârtiei în anaerobă, reciclarea acidului și alte medii gazoase corozive acido-bazice.

Ventilatorul din fibră de sticlă rezistent la coroziune, acizi și alcali este un ventilator industrial de înaltă performanță, special conceput pentru a funcționa în medii care conțin un spectru larg de gaze chimice corozive. Folosind o construcție din plastic armat cu fibră de sticlă (FRP), oferă o rezistență completă la acizi, alcali, săruri și agenți oxidanți - condiții care degradează rapid ventilatoarele metalice.

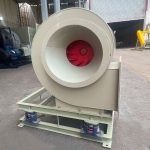

Rotorul are un design curbat înapoi sau radial, turnat din fibră de sticlă de înaltă densitate, cu o distribuție uniformă a rășinii pentru rezistență și echilibru. Carcasa spirală este fabricată din același material compozit FRP, ranforsată cu nervuri de rigidizare pentru a rezista la presiuni statice ridicate. Suprafețele interne sunt acoperite cu un strat de gel rezistent la coroziune pentru o protecție suplimentară împotriva atacurilor chimice și abraziunii.

Arborele, elementele de fixare și baza de susținere sunt fabricate din oțel inoxidabil sau oțel carbon acoperit, în timp ce rulmenții sunt complet etanșați împotriva fluxului de aer. Pentru manipularea gazelor periculoase, ventilatorul poate fi configurat cu un motor antiexplozie și tratament antistatic. Acest design asigură o funcționare sigură chiar și în medii explozive sau reactive chimic.

Parametrii de performanță includ debite de aer de la 800 la 80.000 m³/h și presiuni statice între 500 și 5.000 Pa, cu randamente care depășesc 80%. Ventilatorul este potrivit pentru epuratoare de ceață acidă, extracție de fum de laborator, ateliere de galvanizare, fabrici de îngrășăminte și sisteme de epurare a apelor uzate.

Oferind o combinație completă de durabilitate chimică, rezistență mecanică și eficiență energetică, ventilatorul din fibră de sticlă rezistent la coroziune, acizi și alcali este o soluție de încredere pentru cele mai solicitante aplicații industriale de evacuare și ventilație de proces.