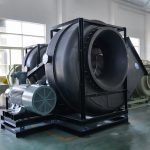

Ventilator FRP de înaltă presiune

Ventilator FRP de înaltă presiune

- Fan model: YHFB 630D

- Fan air volume: 1042~3826 CMH

- Fan pressure: 4421~6219 Pa

- Dispozitiv de etanșare: etanșare inelară din carbon SUS 304

- Mod de transmisie: Transmisie tip cuplaj tip D

- Temperatura de funcționare: ≤80℃

- Eficiența ventilatorului: ≥81.2%

- Viteza ventilatorului: 2900 rpm

- Putere motor: 15 kW

- Diametrul conductei de aer: DN250~DN350 M [Îmbinare amortizor recomandată]

Introducerea produsului

01 Excellent high temperature resistance

The fan test meets the requirements of GB/ T13274-9 (-) fire code test standard, and does not damage in continuous operation for 24 hours under high temperature conditions.

02 High efficiency and energy saving

Using CAD, CFD and other series of analysis and development software, the fan efficiency is greater than 80%, some machine numbers are greater than 85%, and has the characteristics of flat efficiency curve, which is conducive to high efficiency and energy saving.

03 Easy installation, small footprint

It can be directly connected with the air duct and installed on the wall (installation form can be vertical or horizontal), which greatly saves the floor space. Direct motor connection mode, reliable operation.

Scenarii aplicabile

High pressure FRP fan can be widely used in glass fiber process, rare earth extraction, chemical and pharmaceutical, sewage deodorization, paper making anaerobic, acid recycling and other environments containing high pressure corrosive gases.

The High Pressure FRP Fan is a high-performance centrifugal fan designed to provide strong airflow and pressure under demanding industrial conditions. Constructed entirely from fiberglass-reinforced plastic, this fan offers a unique combination of lightweight design, high strength, and superior corrosion resistance, making it suitable for handling corrosive gases, acid vapors, and industrial exhaust streams.

The impeller utilizes backward-curved blades, ensuring efficient conversion of mechanical energy into pressure energy. The fan casing is precision-molded from multi-layer FRP laminates with smooth internal surfaces to minimize airflow resistance. The external structure is reinforced for vibration damping and mechanical stability at high operating speeds. All metallic parts exposed to corrosive gases are fabricated from 304 or 316 stainless steel to ensure complete system durability.

This fan supports direct-drive or belt-drive configurations, with motors available in standard, explosion-proof, or variable-frequency types. Typical operating parameters include air volumes of 1,000–90,000 m³/h and total pressures reaching up to 4,000 Pa. The bearings are housed in an external sealed block to prevent chemical infiltration, and lubrication systems are optimized for long continuous operation.

The High Pressure FRP Fan finds application in acid mist treatment, chemical processing, pharmaceutical production, and industrial gas purification. Its exceptional balance of strength, corrosion resistance, and aerodynamic efficiency makes it a critical component in modern air handling systems where both performance and longevity are essential.