Neposredni ventilator iz ogljikovega jekla

Neposredni ventilator iz ogljikovega jekla

- Fan model: TPC-4.5A

- Fan air volume: 6460-9927CMH

- Fan pressure: 2532-1875Pa

- Ravnotežje: ≤ G2,5 mm/s

- Učinkovitost ventilatorja: ≥ 84%

- Delovna temperatura: ≤ 80%

- Hitrost ventilatorja: 2900 vrt/min

- Moč motorja: 7,5 kW

- Air duct diameter: DN450~DN550 M

- Primerna lokacija: obrat za predelavo kovin

Predstavitev izdelka

Panlijev prezračevalni ventilatorji iz ogljikovega jekla so pridobili različne patentne certifikate in tehnične certifikate za svojo visoko učinkovitost, visoko zmogljivost, nizek hrup in nizke vibracije.

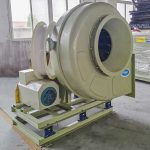

Uporabni scenariji

Široko se uporablja v farmacevtski in kemični industriji, precizni elektroniki, obdelavi kovin, tiskanih vezjih, deodorizaciji odplak, polprevodniških procesih, galvanizaciji in dekapiranju ter na drugih mestih s korozivnimi plini, ki vsebujejo kisle, alkalne in kemične sestavine, za poprodajne storitve.

The Direct Carbon Steel Fan features a direct-drive motor design that ensures efficient power transmission with minimal energy loss. Its all-carbon-steel construction provides superior durability and mechanical integrity, making it suitable for environments with high mechanical stress or abrasive airflows. This fan is commonly used in metallurgy, chemical processing, and heavy manufacturing applications.

By eliminating the need for belt drives, the direct-drive system reduces maintenance requirements, improves efficiency, and ensures precise speed control. The rigidly mounted impeller, dynamically balanced for smooth rotation, delivers steady airflow and pressure performance even under continuous operation.

Available in both axial and centrifugal configurations, the Direct Carbon Steel Fan can be customized with surface coatings, special seals, or explosion-proof motors to meet the demands of specific industrial conditions. It is an ideal choice where compact design, low maintenance, and long service life are priorities.