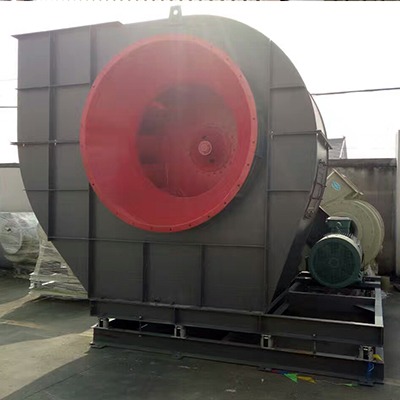

Industrijski prezračevalni ventilator

Industrijski prezračevalni ventilator

- Model ventilatorja: TPC14C

- Prostornina ventilatorja: 100000 CMH

- Tlak ventilatorja: 4000-5000Pa

- Ravnotežje: ≤ G2,5 mm/s

- Učinkovitost ventilatorja: ≥ 84%

- Delovna temperatura: ≤ 80%

- Hitrost ventilatorja: 1315 vrt/min

- Moč motorja: 220 kW

- Premer zračnega kanala: DN1300~DN1400 M

- Primerna lokacija: obrat za predelavo kovin

Predstavitev izdelka

Industrijski ventilatorji se pogosto uporabljajo v procesih obdelave steklenih vlaken, pridobivanju redkih zemelj, kemični in farmacevtski industriji, dezodoriranju odpadnih voda, anaerobni proizvodnji papirja, pridobivanju in uporabi kislin ter drugih okoljih, ki vsebujejo korozivne pline pod visokim tlakom. Centrifugalni ventilatorji za čiščenje industrijskih odpadnih plinov imajo široko paleto uporabe, so primerni za različne delovne pogoje, so učinkoviti in energetsko varčni ter ustvarjajo dobiček in prihranijo stroške.

Prednosti izdelka

Uporaba neposredne povezave med motorji in rotorji zmanjšuje izgube zaradi prezračevalnega upora, kot so kanali v obliki črke S, izboljšuje učinkovitost in zmanjšuje varnostna tveganja in težave z vzdrževanjem, ki jih povzročajo kanali v obliki črke S, s čimer se izboljšuje obratovalna varnost.

Izberite visokokakovosten eksplozijsko varen motor, posebej zasnovan za ventilatorje, in ga namestite v komoro za izolacijo pretoka z določeno napetostno upornostjo, da ga izolirate od zračnega toka, ki vsebuje plin v rudniku. Komora za izolacijo pretoka je opremljena z zračnim kanalom, ki se samodejno prezračuje z atmosfero, kar omogoča odvajanje toplote in vodenje pretoka.

Uporabni scenariji

Široko se uporablja v procesih steklenih vlaken, pridobivanju redkih zemelj, kemični in farmacevtski industriji, dezodoriranju odpadnih voda, anaerobni proizvodnji papirja, predelavi in uporabi kislin ter drugih okoljih, ki vsebujejo korozivne pline pod visokim tlakom. Industrijski ventilatorji imajo široko paleto uporabe, so primerni za različne delovne pogoje, so učinkoviti in energetsko varčni ter ustvarjajo dobiček in vam prihranijo stroške.

Industrijski prezračevalni ventilator je zasnovan za zagotavljanje učinkovite izmenjave zraka v tovarnah, delavnicah, predorih in skladiščih z dovajanjem svežega zraka ali odvajanjem onesnaženih plinov in hlapov. Za razliko od gospodinjskih prezračevalnih enot industrijski modeli delujejo pod visokimi obremenitvami in v zahtevnih okoljih, kar zagotavlja stabilen pretok zraka z dolgotrajno vzdržljivostjo. Glede na smer pretoka zraka so lahko industrijski prezračevalni ventilatorji aksialni, centrifugalni ali mešani, vsak pa je optimiziran za specifične zahteve glede tlaka in prostornine.

Pri centrifugalnih modelih zrak vstopa aksialno in izstopa radialno, kar ustvarja višji tlak, primeren za kanalske sisteme. Aksialni modeli zagotavljajo večje količine zraka z nižjim tlakom, kar je idealno za prezračevanje odprtih prostorov. Ohišje in rotor sta običajno izdelana iz ogljikovega jekla, nerjavečega jekla ali aluminijeve zlitine in premazana z antikorozijsko prevleko za daljšo življenjsko dobo. Motorji so izbrani glede na potrebo po moči in okoljske pogoje, vključno z možnostmi eksplozijsko varnega in s spremenljivo hitrostjo.

Pri zasnovi je pozornost namenjena učinkovitosti pretoka zraka, porabi energije in zmanjšanju hrupa. Rotorji so dinamično uravnoteženi, vhodni stožci pa so poenostavljeni, da se zmanjša turbulenca. Ležaji so zatesnjeni in mazani za odpornost na visoke temperature. Za pline, obremenjene s prahom ali korozivnimi plini, je lahko notranjost ventilatorja obložena z materiali proti obrabi ali kislinam. Izbirna oprema vključuje vhodne filtre, vremensko odporne pokrove, izolatorje vibracij in dušilce zvoka.

Industrijski prezračevalni ventilatorji se pogosto uporabljajo v proizvodnih delavnicah, avtomobilskih tovarnah, tekstilnih tovarnah, predorih, podzemnih parkiriščih in kmetijskih prezračevalnih sistemih. Učinkovito vzdržujejo kakovost zraka, uravnavajo vlažnost ter odstranjujejo toploto in hlape. Zmogljivost pretoka zraka se običajno giblje od 3000 m³/h do 250.000 m³/h, s tlakom med 300 Pa in 5000 Pa. Zasnovani so za neprekinjeno delovanje in minimalno vzdrževanje, zato zagotavljajo zanesljivo prezračevanje in prispevajo k energetsko učinkovitim in varnim industrijskim okoljem.