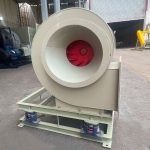

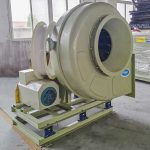

Stainless Steel Anti-Corrosion Fan

Stainless Steel Anti-Corrosion Fan

- Fan model: TPE 6.0C

- Fan air volume: 9337~14753 CMH

- Fan pressure: 4293~3257 Pa

- Balance level: ≤ G2.5 mm/s

- Operating temperature: ≤ 80 ℃

- Fan efficiency: ≥ 69.4%

- Fan speed: 2550 rpm

- Motor power: 18.5KW

- Air duct diameter: DN400~DN500 mm

- Fan color: Silver 【SUS 304】

Product Introduction

The selection of materials for stainless steel anti-corrosion fans is based on the actual gas composition in contact. By utilizing the unique characteristics of stainless steel, it can withstand some corrosive gases, such as acetaldehyde, alcohol, acetone, acetylene, etc. It is equipped with a frequency conversion speed control motor for rust prevention and corrosion prevention, which is easy to operate and operates smoothly 24 hours a day, ensuring long-term use.

More than 20 patents have been certified, including high-tech enterprises, Jiangsu Province's Top 100 Su Shang Enterprises, AMCA members in the United States, Chinese integrity enterprises, and third-party testing qualifications. With a ten-year brand, we reduce worries and provide you with peace of mind when using.

Product Scenarios

Stainless steel anti-corrosion fans are suitable for environments such as chemical plants, electroplating plants, sewage tanks, new energy, experimental sites, and underground bases; Understanding the actual gas working conditions and distinguishing the corrosion levels of stainless steel mainly relies on technical experiments and practical experience. Reasonable data reflection helps in material selection and reduces the trouble of material corrosion. Regular maintenance can also save costs in operation.

The Stainless Steel Anti-Corrosion Fan is designed specifically for corrosive gas exhaust, chemical ventilation, and process air handling in harsh industrial environments. Constructed from premium-grade 304, 316, or duplex stainless steel, it provides exceptional resistance to acidic, alkaline, and saline atmospheres, ensuring long-term durability and consistent performance.

The centrifugal impeller adopts an optimized backward or radial blade design, depending on pressure and flow requirements. Each component is precision-welded and polished, preventing crevice corrosion and ensuring smooth airflow. The fan is engineered for continuous-duty operation, maintaining efficiency across a wide range of flow rates and static pressures.

The motor housing is isolated from the airstream to protect against chemical vapors, while the drive shaft is equipped with mechanical seals or PTFE packing for gas-tight operation. Bearings are sealed and lubricated for extended lifespan. The entire assembly is vibration-balanced and tested to meet industrial noise and safety standards.

The Stainless Steel Anti-Corrosion Fan is widely used in chemical manufacturing, pharmaceutical production, wastewater treatment, laboratories, and marine engineering, where both hygiene and corrosion resistance are critical. Its modular design allows easy integration with duct systems, scrubbers, and filters.

Offering high efficiency, easy maintenance, and uncompromising durability, this fan ensures reliable performance in any application exposed to chemically aggressive or moisture-rich environments.