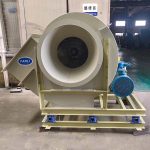

Ljudisolerad låda för fläkt i glasfiber

Ljudisolerad låda för fläkt i glasfiber

- Fläktmodell: FB 900C

- Fläktluftvolym: 37857~24053 CMH

- Fläkttryck: 2658-1605 Pa

- Fläktriktning: Vänsterrotation 180 grader – A-riktning

- Balansnivå: ≤ 2,5 mm/s

- Driftstemperatur: ≤ 80 ℃

- Fläkteffektivitet: ≥ 82,2%

- Fläkthastighet: 1620 rpm

- Motoreffekt: 30 kW

- Luftkanaldiameter: DN800~DN1000 [stöder anpassad utseendefärg]

Produktintroduktion

Glasfiberfläkten i den ljudisolerade lådan uppfyller bullerstandardgränserna. Fläktutrustningen körs kontinuerligt i 24 timmar, med lågt ljud, låga vibrationer, glansigt utseende och energibesparing. Ljudisolationen registreras enligt datorteststandarder, och faktiska mätbulleranalyser utförs för att förbättra fläktens övergripande ljudisoleringseffekt.

Inspektionen av D-typ rörledningar utförs med en centrifugalfläkt som uppfyller kraven i GB-T1236-2000-standarden för luftkanalinspektion. Centrifugalfläktens hölje och impeller är heltäckande tillverkade med en oljebadsrullagerlåda och en luftkyld kylmetod. Den industriella produktionen har samma specifikationer, bekväm drift, snabb drifttid, låg användningskostnad och utbyte av centrifugalfläktar.

PANLI, som har avancerad teknik inom vindkraftverk och erfarna seniora experter, kombinerar de två styrkorna. Genom att kombinera exakta beräkningar med utveckling av datainsamlingsprogramvara som CAD, 3D, CFD etc. kan skräddarsydda konstruktioner göras för att säkerställa normal användning av fläktar.

Tillämpliga scenarier

Ljudisolerade fläktar av glasfiberförstärkt plast används ofta i sura och alkaliska miljöer, såsom avloppsrening, biologisk deodorisering, läkemedels- och kemisk industri, elektroplätering och syratvätt, universitetslaboratorier, elektroniska halvledare etc. Miljöföroreningar blir allt allvarligare, och det finns också betydande krav på buller som genereras av maskiner. Ljudisolerade fläktar används för närvarande i stor utsträckning för att minska graden av bullerföroreningar, effektivt blockera bullerspridning, röra sig mer stabilt, rotera tystare och är lämpliga för användning i avloppsrening och biologisk deodorisering.

Glasfiberfläktens ljudisolerande låda är ett avancerat ljudreducerande höljessystem utformat för FRP- eller PP-fläktar som arbetar i kemiska eller korrosiva miljöer. Den integrerar höghållfasta glasfiberförstärkta plastmaterial (FRP) med flerskiktad akustisk isolering för att ge både korrosionsskydd och överlägsen ljuddämpning.

Detta ljudisolerade hölje är speciellt utformat för användning med fläktar som hanterar sura, alkaliska eller luktbelastade avgaser, såsom de som finns i metallbeläggningsverkstäder, laboratorier eller miljövänliga luktreduceringssystem. Glasfiberhöljet motstår kemisk korrosion, UV-nedbrytning och fuktinträngning, vilket säkerställer lång livslängd även under tuffa förhållanden.

Internt är den ljudisolerade lådan klädd med akustiskt skum och perforerade kompositpaneler som absorberar luftburet och mekaniskt buller som genereras av fläktdrift. Konstruktionen uppnår betydande ljuddämpning – vanligtvis med en bullerminskning på 15–25 dB(A) – utan att kompromissa med ventilationsprestanda.

Kapslingens interna struktur möjliggör ett jämnt luftflöde, vilket förhindrar mottryck eller turbulens. Fläktmotorn kan monteras externt med en tätad koppling för att isolera elektriska komponenter från frätande gaser. Åtkomstpanelerna är utrustade med packningsförsedda dörrar för enkelt underhåll samtidigt som de bibehåller lufttätheten.

Glasfiberfläktens ljudisolerade låda är konstruerad för prestanda och kombinerar kemisk resistens, strukturell styvhet och ljuddämpning i ett system. Den är lämplig för integration med FRP-centrifugalfläktar, PP-frånluftsfläktar eller högtrycksfläktar i FRP, vilket ger en tyst och korrosionssäker ventilationslösning i industriella luftreningssystem.