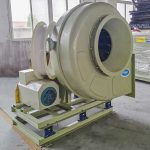

FRP-centrifugalfläkt i glasfiber

FRP-centrifugalfläkt i glasfiber

- Fläktmodell: FB1250C

- Fläktluftvolym: 49162~68811 CMH

- Fläkttryck: 2544~1851 Pa

- Fläktriktning: vänsterrotation 45 grader -L

- Balansnivå: ≤ 2,5 mm /s

- Fläkteffektivitet: ≥ 84%

- Driftstemperatur: ≤ 80 ℃

- Fläkthastighet: 950 rpm

- Motoreffekt: 55 kW

- Luftkanaldiameter: DN1200 [Rekommenderas ±10%]

Produktintroduktion

01 Materialteknik

Glasfibercentrifugalventilator är tillverkad av vinylesterharts av vinylesterkvalitet, rent glasfibermaterial, gjuten i skalform, pumphjulets femaxliga graveringsteknik, hastighetstest, sprängskyddstest, rotorbalans ≤2,0 mm/s, lång servicecykel, stabil vindhastighet, högt vindtryck, god ventilationseffekt.

02 Företagsutveckling

30 000 kvadratmeter produktionsbas, årlig produktion på 10 000 set, strikt kvalitetskontroll av fläktar, humaniserad spårbarhetshantering, företaget genom AMCA-testning och certifiering av fläktar, brådskande beställningar inom 2 dagar med snabb leverans, 24 timmars online-konsulttjänster, 1V1-ingenjörer skräddarsydda inom 72 timmar med kvalitetssäkring, för att användare ska kunna lösa olika problem, eftermarknadsskydd.

FRP-centrifugalfläkten i glasfiber är en industriell luftbehandlingsanordning konstruerad för att transportera korrosiva gaser och ångor med hög effektivitet och tillförlitlighet. Fläktens konstruktion använder glasfiberförstärkt plast, vilket säkerställer motståndskraft mot syror, alkalier och de flesta kemiska ångor som finns i industriell produktion. Den fungerar enligt centrifugalprincipen, där luft sugs in axiellt och avges radiellt genom ett spiralhus, vilket producerar högt statiskt tryck med kontrollerade flödeshastigheter.

Denna centrifugalfläkt har ett aerodynamiskt optimerat pumphjul med bakåtböjda eller radiella skovlar, konstruerat för energieffektiv drift och lågt ljud. Pumphjulet och höljet är tillverkade genom precisionsgjutning, vilket säkerställer utmärkt dimensionsstabilitet och jämn prestanda även under fluktuerande belastningar. Lagren är monterade utanför luftflödesvägen för att minimera exponering för korrosiva gaser, vilket förlänger driftstiden och minskar underhållsfrekvensen.

Motoralternativen inkluderar standard IP55-motorer, explosionssäkra typer eller frekvensomriktare (VFD) för justerbar hastighetsreglering. Beroende på systemkrav kan fläkten monteras horisontellt eller vertikalt. Luftkapaciteten varierar vanligtvis från 500 m³/h till 100 000 m³/h, med tryck mellan 200–3 500 Pa. Den släta insidan av FRP-höljet säkerställer minimalt luftmotstånd och förhindrar ansamling av kemiska rester.

Vanliga tillämpningar inkluderar kemiska processanläggningar, batteritillverkning, halvledarproduktion, betningslinjer och laboratorieavgasanläggningar. Dess höga kemiska resistens och långa livslängd gör FRP-centrifugalfläkten till en idealisk lösning för krävande miljöer som kräver stabilt luftflöde och minimal driftstopp.