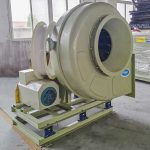

Högtryckscentrifugal glasfiberfläkt

Högtryckscentrifugal glasfiberfläkt

- Fläktmodell: HFB710C

- Fläktluftvolym: 8697~17812CMH

- Fläkttryck: 4040~3320 Pa

- Balansnivå: ≤ 2,5 mm /s

- Fläkteffektivitet: ≥ 84%

- Driftstemperatur: ≤ 80 ℃

- Fläkthastighet: 1830 rpm

- Motoreffekt: 30 kW

- Luftkanaldiameter: DN400*500

Produktintroduktion

01 Materialteknik

Högtryckscentrifugalfläkt i glasfiber har en packningsaxeltätning med petalpackning, god tätningsprestanda, speciell förebyggande av gasläckage, kan användas i fabriker, laboratorier och andra speciella tillfällen, skalet och pumphjulet är tillverkade av glasfibermaterial, integrerad formgjutning, manuell förstärkningsprocess, korrosions- och syraförebyggande, strikt kontroll av utrustningens driftseffektivitet.

02 Företagsutveckling

Med omfattande patent "en centrifugalfläkt för avgasuppsamling", Kinas energibesparande produktcertifiering, Kinas energieffektivitetsetikettcertifiering, garanti.

03 Eftermarknadsservice

Om utrustningen slutar fungera, kontakta oss i tid, kundtjänst online dygnet runt, 72 timmar om dygnet för underhåll på plats, Panli-fläkten utför regelbundet undersökningar och inspektioner av utrustningens driftstatus, professionell teknik för att lösa alla typer av problem som kunderna stöter på, nationell logistikleverans, kvalitetssäkring.

Högtryckscentrifugalfläkten i glasfiber är en avancerad luftbehandlingsenhet konstruerad för industriella miljöer där högt statiskt tryck och kemisk resistens är avgörande. Den fungerar enligt centrifugalprincipen, drar luft axiellt och släpper ut den radiellt genom ett exakt konturerat FRP-spiralhölje, vilket ger ett kraftfullt luftflöde vid förhöjt tryck. Fläkten är tillverkad av högkvalitativ glasfiberförstärkt plast och erbjuder exceptionell prestanda i korrosiva miljöer, vilket gör den idealisk för kemisk, farmaceutisk och metallurgisk industri.

Impellerns design har bakåtböjda vingprofilblad, vilket ger optimal tryckomvandling med minskad energiförlust. Varje impeller är dynamiskt balanserad enligt ISO-standarder för att säkerställa smidig drift och minimera vibrationer. Pumphuset är gjutet som en sömlös enhet för att eliminera läckage och förbättra kemisk resistens. Invändiga ytor är belagda med korrosionsskyddande hartsgelbeläggningar som förhindrar nedbrytning från syra- och alkaliångor.

Fläkten drivs av högeffektiva industrimotorer och stöder direkt- eller remdrivna konfigurationer, med explosionssäkra eller varvtalsreglerade motorer som tillval beroende på processkrav. Typiska prestandaspecifikationer inkluderar luftflöden från 1 500 till 120 000 m³/h och totaltryck upp till 5 000 Pa. Lagren är placerade utanför gasvägen, vilket säkerställer isolering från korrosiva medier och främjar lång livslängd.

Högtryckscentrifugalfläkten i glasfiber används ofta i kemiska skrubbrar, betningssystem, rökgasutsugningsanläggningar och industriella avgasledningar. Med sin kombination av högt tryck, lågt ljud och kemisk hållbarhet representerar den en pålitlig lösning för kontinuerlig drift i tuffa industriella miljöer.