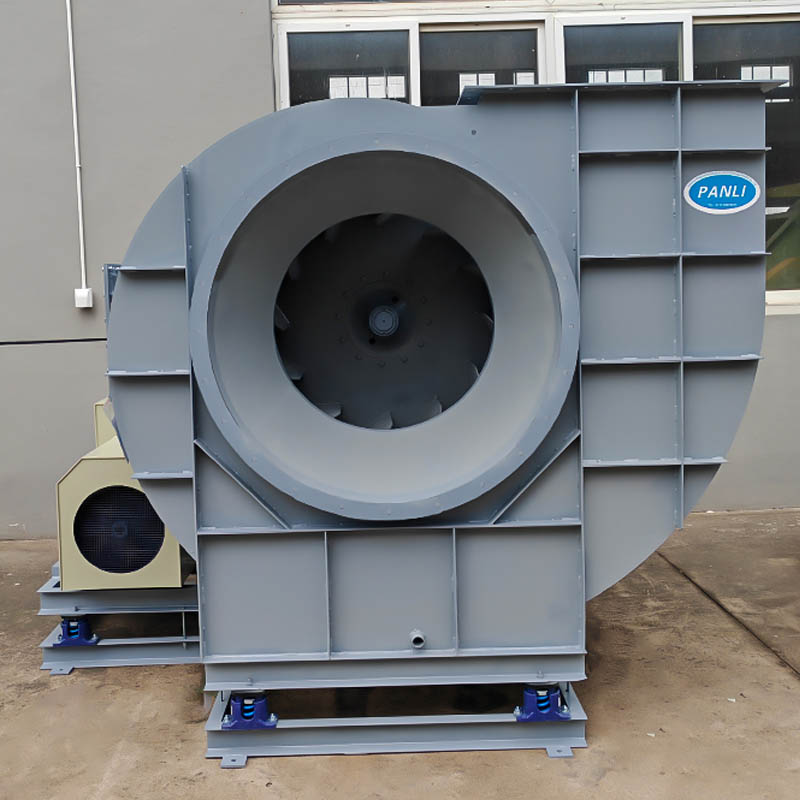

Centrifugalfläkt med medelhögt tryck

Centrifugalfläkt med medelhögt tryck

- Fläktmodell: TPC 8.0C

- Fläktluftvolym: 21886~35415 CMH

- Fläkttryck: 2931-2176 Pa

- Balansnivå: ≤ 2,5 mm/s

- Fläkteffektivitet: ≥ 84%

- Fläkthastighet: 1870 rpm

- Motoreffekt: 30 kW

- Luftkanaldiameter: DN800~DN900 M

- Driftstemperatur: rumstemperatur [särskilda instruktioner krävs för hög temperatur]

Produktintroduktion

Den övergripande användningen av Q235A, korrosionsskyddande och temperaturbeständig beläggning, källproduktionsteknik, höljet använder integrerad svetsformning, det yttre skalet har hög hållfasthet och deformeras inte lätt, och är utrustat med tätad packning för att undvika gasläckage. Alla använder metallimpellrar för mer stabil och effektiv drift, vilket sparar energiförbrukning, lämplig för högtemperaturmiljöer som förbränningsugnsavgaser.

En tillverkare som integrerar fläktproduktion och försäljning, med tio års produktionserfarenhet, strikt kvalitetskontroll och professionella tekniska lösningar på olika kundproblem. Företaget har erhållit certifikat som China Energy Conservation Product Certification, China Energy Efficiency Labeling Certification, EU CE-certifiering och mer än 30 patentcertifieringar, vilket garanterar säkerheten.

24-timmars kundservice online, professionell personlig kommunikation, kan erbjuda gratis produktvalstjänster, rikstäckande logistikleverans- och installationstjänster, livstidsgaranti och regelbunden drift och inspektion av utrustning, boka underhåll på plats och anlända till platsen inom 72 timmar för att lösa problem.

Mellantryckscentrifugalfläkten är konstruerad för att överbrygga gapet mellan lågtrycksfläktar och högtrycksfläktar, och ger en balanserad kombination av luftflödesvolym och statiskt tryck. Dess typiska tryckområde ligger mellan 1 000 och 4 000 Pa, vilket gör den idealisk för allmän industriell ventilation, materialtransport och processlufthantering. Fläkten använder standardcentrifugalmekanism – luft dras in i mitten av pumphjulet och blåses ut radiellt under centrifugalkraft.

Pumphjulet har vanligtvis en bakåtböjd eller radiell bladkonfiguration, tillverkad av kolstål eller rostfritt stål. Denna design erbjuder både hög effektivitet och slitstyrka. Fläkthuset är svetsat av tjocka stålplattor med förstärkningsribbor, vilket säkerställer mekanisk hållfasthet och minimal deformation under kontinuerlig drift. Axelaggregaten använder precisionslager smorda med värmebeständigt fett, och kylanordningar finns vid behov.

Medeltryckscentrifugalfläktar finns tillgängliga i direktdrivna, kopplingsdrivna och remdrivna konfigurationer, vilket ger flexibilitet baserat på applikation. Motorn väljs utifrån belastning, driftsmiljö och styrkrav, med frekvensomvandlare som tillval för variabel hastighetsreglering. Fläkten kan utrustas med spjäll, ljuddämpare och flexibla kontakter för att förbättra prestanda och minska vibrationer.

Användningsområden inkluderar dammuppsamling, torksystem, luftreningsenheter, små ugnar, pneumatisk transport och ventilation av stora verkstäder. Luftflödeskapaciteten varierar från 1 000 m³/h till 120 000 m³/h. Dessa fläktar kännetecknas av stabil drift, enkelt underhåll och hög effektivitet. Deras design säkerställer jämn prestanda under måttliga motståndsförhållanden, vilket gör dem till en av de mest mångsidiga centrifugalfläkttyperna i industriella luftsystem.