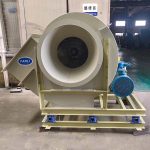

พัดลมไฟเบอร์กลาสป้องกันการกัดกร่อน

พัดลมไฟเบอร์กลาสป้องกันการกัดกร่อน

- Fan model: FB900C

- Fan air volume: 25686~40428 CMH

- Fan pressure: 3031~1830 Pa

- อุณหภูมิในการทำงาน: ≤80℃

- ประสิทธิภาพพัดลม: ≥84%

- ความเร็วพัดลม: 1730 รอบต่อนาที

- กำลังมอเตอร์: 37 กิโลวัตต์

- Air duct diameter: DN800~DN1000 mm

- Chimney lift: 10 meters

- Tower lift: 20 meters [It is recommended to install anti-leakage sealing device]

การแนะนำผลิตภัณฑ์

01 Selection of raw materials

The raw material adopts Vinyleser alken-based glass fiber reinforced plastic resin, ultraviolet resistant Marine coating, aging and corrosion resistance. The Japanese source production technology combined with its own research and development, suitable for all kinds of chemical, electroplating, biological and sewage deodorization and other corrosive environment.

02 Enterprise strength

Service, free on-site survey, provide design schemes and technical consulting services, regular inspection of fan operation, promise a one-year warranty, still do effective protection of equipment after the period, national logistics delivery to the door, on-site free guidance installation training.

สถานการณ์ที่สามารถใช้ได้

Fiberglass anticorrosive fan is mainly used in pharmaceutical industry, petrochemical industry, precision electronics, metal processing, PCB circuit board, sewage deodorization, semiconductor process, electroplating pickling and other places containing acid and alkali components, and corrosive gases in the chemical industry, a wide range of application sites, suitable for a variety of working conditions, fan efficiency is stable, for you to increase profits, save costs, Fiberglass fan is preferred.

The Fiberglass Anticorrosive Fan is purpose-built for chemical and industrial environments where metallic fans are quickly degraded by exposure to corrosive vapors or liquids. Manufactured from fiberglass-reinforced plastic (FRP), it exhibits exceptional resistance to acids, alkalis, and salt-laden air, ensuring consistent operation in harsh atmospheric conditions.

The fan adopts a centrifugal or axial-flow configuration, depending on application needs. The FRP impeller is precision-balanced and reinforced for mechanical rigidity, while the volute casing is formed as a seamless FRP shell with corrosion-resistant gel coating. The overall design ensures smooth airflow, low vibration, and minimal energy loss. Bearings and drive components are mounted externally, protected by chemical seals.

Motors are available in standard, explosion-proof, or VFD-compatible configurations, offering flexible control for various airflow demands. The fan’s lightweight construction allows easy installation on rooftops, ducts, or scrubber systems. Its long-lasting FRP structure resists corrosion even in environments containing hydrochloric acid, sulfur dioxide, or ammonia.

Airflow capacity ranges from 800 to 100,000 m³/h, with static pressures up to 4,500 Pa. The Fiberglass Anticorrosive Fan is widely used in chemical plants, plating lines, fertilizer production, wastewater treatment, and laboratory exhaust systems. It represents a reliable, maintenance-free solution that ensures safe and efficient operation in the presence of aggressive chemical gases.