Вентилятор для біологічної дезодорації

Вентилятор для біологічної дезодорації

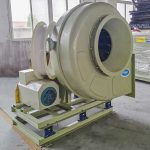

- Модель вентилятора: FB 1000C

- Об'єм повітря вентилятора: 27931~40415 куб.см/год

- Тиск вентилятора: 3031-1660 Па

- Напрямок вентилятора: обертання на 90 градусів праворуч (напрямок E)

- Шум вентилятора: ≤ 75 дБ

- Робоча температура: ≤ 80 ℃

- Матеріал вентилятора: повністю армований склопластик (FRP)

- Швидкість вентилятора: 1230 об/хв

- Потужність двигуна: 30 кВт

- Діаметр повітропроводу: DN900~DN1100 【Спеціальний пристрій для запобігання запаху та протіканню 】

Вступ до продукту

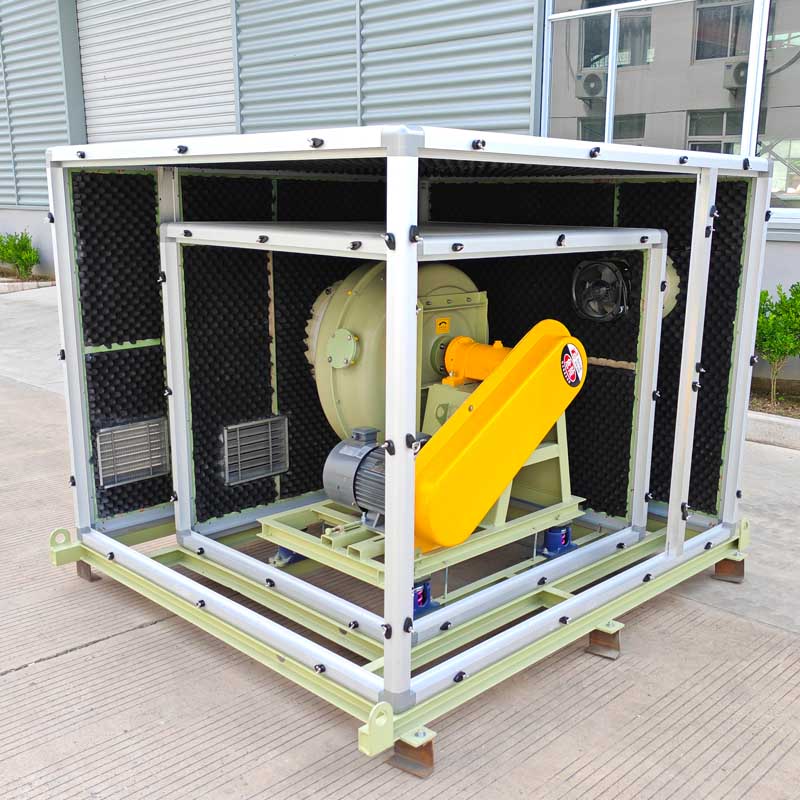

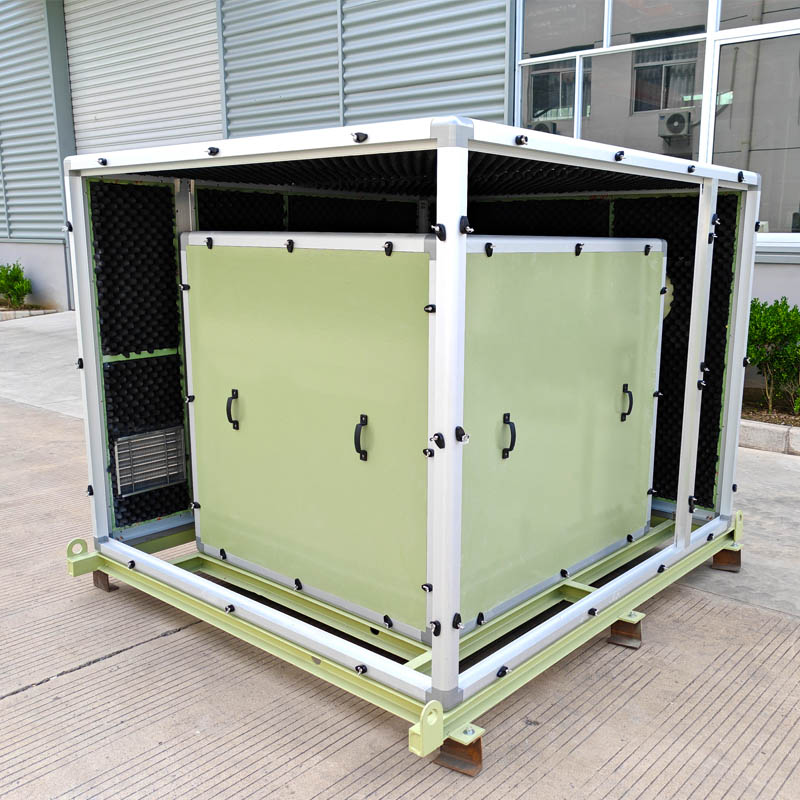

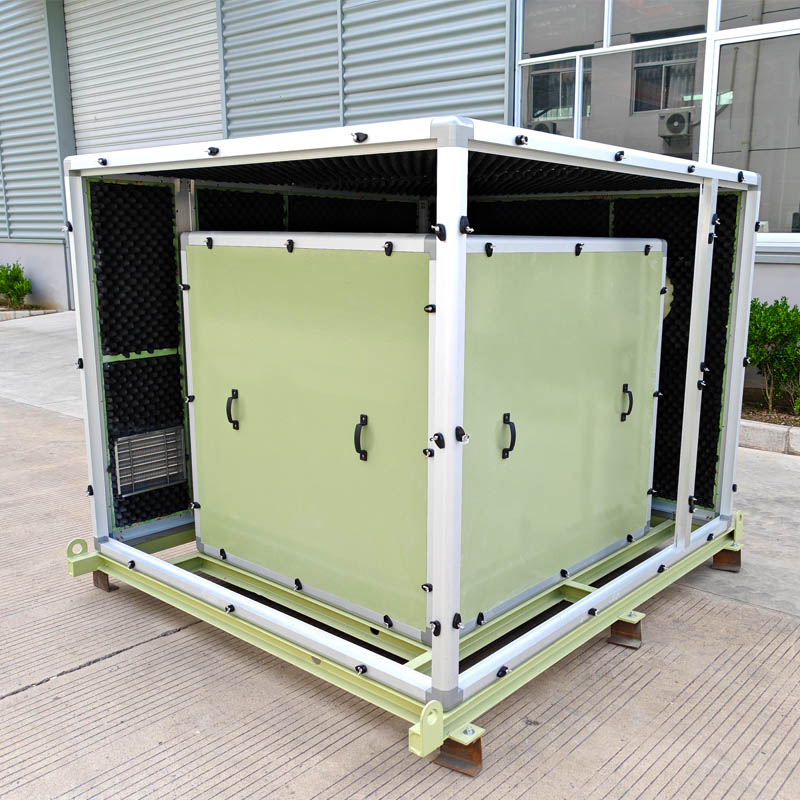

Вентиляторний дезодоруючий блок виготовлений повністю зі склопластику (FRP), із зовнішньою панеллю зі скловолокна та внутрішньою звукоізоляційною бавовною. Він оснащений незалежним вентилятором охолодження, має дверцята для доступу, дренажні клапани та отвори для проводки. Його легко обслуговувати на подальшому етапі, він відповідає стандартам шуму, економить енергію та має низький рівень вібрації. Обладнання працює без жодних збоїв протягом 24 годин.

М'яке з'єднання з ПВХ на вході та виході вентилятора блокує поширення вібрації, запобігає загальній вібрації звукоізоляційної коробки та трубопроводу, а також створює непотрібні втрати. Масляна коробка підшипників та підшипники кочення зменшують тертя та збільшують термін служби. Рівень шуму можна зменшити на 5-15 децибелів, і їх можна використовувати з фланцевими з'єднаннями трубопроводів D-типу.

Цілодобова індивідуальна консультація, цілодобове онлайн-прослуховування, безкоштовне розроблення технічних рішень, вибір моделей вентиляторів, підтримка налаштування, післяпродажне обслуговування: вирішення проблем протягом 1 години, безтурботне післяпродажне обслуговування, відсутність ручного обслуговування, одноразова покупка, довічне обслуговування.

Застосовні сценарії

Вентилятор біологічної дезодоруючої коробки має різноманітне застосування та умови роботи, і зазвичай використовується в таких середовищах, як біологічна дезодорація, дезодорація стічних вод та очищення від запахів у тваринництві. Фактично, шумове забруднення стає все більш серйозним, впливаючи на щоденний відпочинок мешканців поблизу. Постійні скарги на проблеми з шумом також є головним болем для власників бізнесу. Скарг забагато, і неминучі збитки. Вибір звукоізоляційної коробки біологічної дезодорації не тільки зменшує шум, але й блокує витік запахів вдруге. Це може бути успішно прийнято. Наразі галузь біологічної дезодорації широко використовується, що робить її більш стабільною, тихою та придатною для проектів біологічного контролю запахів.

Вентилятор для біологічної дезодорації – це спеціалізований вентиляційний пристрій, розроблений для циркуляції повітря в системах біологічного видалення запахів. Він зазвичай застосовується на очисних спорудах стічних вод, компостних установках та системах хімічного очищення газів, де відпрацьовані гази повинні проходити через біофільтри або камери біологічної дезодорації.

Виготовлений переважно зі склопластику (FRP) або поліпропілену (PP), цей вентилятор здатний довго працювати в агресивних та вологих середовищах. Він забезпечує стабільний потік повітря для підтримки оптимальної біологічної активності в дезодоруючому середовищі. Робоче колесо аеродинамічно оптимізоване для рівномірного розподілу повітряного потоку, мінімізуючи мертві зони в дезодоруючому коробці.

Вентилятор характеризується низьким енергоспоживанням та безперервною роботою, при цьому двигун зазвичай встановлюється поза газовим потоком для запобігання корозії. Доступні додаткові вибухобезпечні або водонепроникні конфігурації. Корпус та вхідний отвір розроблені для легкої інтеграції з корпусами біологічних фільтрів, а доступ для обслуговування спрощений завдяки знімним кришкам.

Окрім стійкості до корозії, вентилятор біологічної дезодоруючої камери розроблений для забезпечення стабільного потоку повітря за змінних рівнів опору системи. Його широка крива продуктивності враховує коливання вологості та концентрації газу, які є поширеними в системах біофільтрів.

Розроблений для надійності, низького рівня шуму та хімічної стійкості, вентилятор забезпечує постійну подачу свіжого кисню та управління вихлопними газами, необхідні для ефективного біологічного контролю запахів.