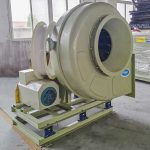

Енергозберігаючий вентилятор зі скловолокна

Енергозберігаючий вентилятор зі скловолокна

- Модель вентилятора: FB1400C

- Об'єм повітря вентилятора: 72704~101763 куб.см/год

- Тиск вентилятора: 2229~2813 Па

- Напрямок вентилятора: лівий 45 градусів (напрямок L)

- Рівень балансу: ≤ 2,5 мм/с

- Робоча температура: ≤80℃

- Ефективність вентилятора: ≥84%

- Швидкість вентилятора: 980 об/хв

- Потужність двигуна: 110 кВт

- Діаметр повітропроводу: DN1300~DN1500 мм [Рекомендований амортизатор]

Вступ до продукту

01 Переваги процесу

Вибір сировини, смола марки, спеціальна обробка стійкості до кислотних та лужних газів, п'ятиосьовий процес гравірування, інтегроване лиття під тиском, легка вага, висока міцність, енергозбереження, підходить для всіх видів хімічної промисловості, гальваніки, біології та напівпровідників та інших місць використання.

02 Енергозберігаючі продукти

"Енергозбереження"

03 Післяпродажне обслуговування

Надання технічних консультацій щодо обслуговування, огляд об'єкта, регулярна перевірка стану вентиляторів, річна безкоштовна страховка, довічна гарантія, доставка національною логістикою.

Застосовувані сценарії

Енергозберігаючий відцентровий вентилятор зі скловолокна підходить для напівпровідникових процесів, медичних лабораторій, хімічних викидів, металургійної обробки, біологічної дезодорації та інших місць, де використовуються кислотні та лужні гази. Застосовуване робоче середовище має різноманітні можливості, підвищує ефективність, економить викиди енергії, створює корпоративний прибуток, економить виробничі витрати, має довічне обслуговування, вирішує непередбачені проблеми, забезпечує професійне керівництво та навчання.

Енергозберігаючий вентилятор зі скловолокна являє собою нове покоління високоефективного, стійкого до корозії обладнання для обробки повітря, розробленого для безперервної роботи в хімічних, екологічних та морських вентиляційних системах. Виготовлений з сучасних матеріалів, армованих скловолокном (FRP), цей вентилятор досягає чудової корозійної стійкості, зберігаючи при цьому чудову аеродинамічну ефективність та низьке енергоспоживання.

Енергозберігаюча конструкція вентилятора базується на оптимізованій геометрії лопатей, розробленій за допомогою обчислювального моделювання гідродинаміки (CFD). Робоче колесо має аеродинамічні лопаті із загнутими назад загинами, що дозволяє ефективно перетворювати механічну енергію на повітряний потік з мінімальною турбулентністю та втратою тиску. У поєднанні з гладкою спіральною оболонкою з армованого скловолокном та вхідним розтрубом, повітряний потік залишається стабільним та ламінарним протягом усієї роботи.

Структурні компоненти, включаючи вал, підшипники та раму, виготовлені з нержавіючої сталі або алюмінієвого сплаву з покриттям для додаткової стійкості до корозії. Підшипники встановлені зовні, з додатковим повітряним або водяним охолодженням для безперервної роботи в гарячих середовищах. Легка конструкція з склопластику зменшує механічне навантаження на двигун та фундамент, знижуючи вібрацію та подовжуючи термін служби обладнання.

Доступний як в осьовій, так і в відцентровій конфігураціях, вентилятор забезпечує продуктивність повітряного потоку від 1000 до 120 000 м³/год та номінальний тиск до 3500 Па, залежно від застосування. У поєднанні з частотним приводом (ЧРП) він забезпечує оптимізовану продуктивність за різних умов потоку, досягаючи економії енергії до 301 TP3T порівняно зі звичайними сталевими вентиляторами.

Енергозберігаючий вентилятор зі скловолокна ідеально підходить для хімічних заводів, очисних споруд, цехів з виробництва добрив та систем захисту навколишнього середовища, пропонуючи надійний баланс ефективності, довговічності та екологічності у вимогливих промислових умовах застосування.